Resource center

Featured article

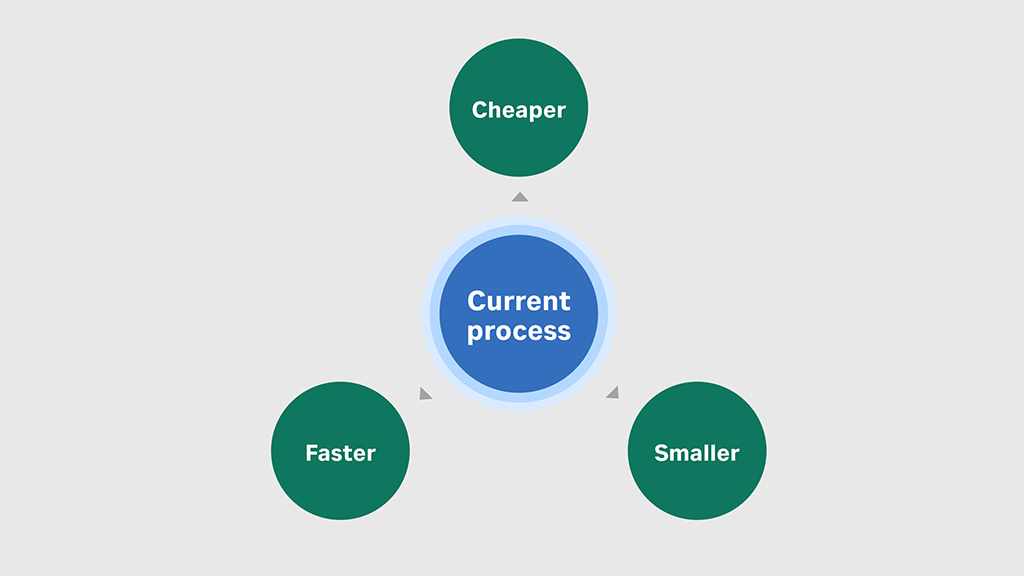

Process Intensifier App

Select the parameters that are used in your upstream bioreactor or downstream capture step then gain insights on how your process can be intensified.

Popular articles

The promise and challenges of mRNA vaccine development

The COVID-19 pandemic brought mRNA vaccines to the spotlight with the rapid release of highly efficacious vaccines by Pfizer/BioNTech and Moderna.

Evaluating the economics of today’s biomanufacturing strategies

Whether you’re waiting for a production slot with a qualified CDMO or ready to build, a flexible strategy can help you scale quickly, to produce the right quantity at the right time..

Facilitating workforce development

A case study on improving single-use training through vendor and end-user collaboration.