Lithium-Ion Battery Solutions Charged for Success

Filtration Solutions to Help You Drive Improved Quality and Efficiency

With our proven experience in filtration and separation technologies across a broad spectrum of industries, we are your perfect partner in the lithium-ion battery sector. Our advanced technical expertise acquired from partnering with customers in markets from mining, microelectronics, specialty chemicals, polymers and automotive is already being applied to customers across the lithium-ion value chain. Combining global reach with local knowledge, we can offer exceptional support and efficient filtration and separation solutions to help you reach your quality and efficiency goals.

From mining and mineral processing to final assembly, we can help you achieve greater productivity in the lithium-ion battery market by:

- Improving end-product quality

- Reducing costly downtime and maintenance operations in your production processes

Select an area of interest to find out more:

-

Base Materials

-

Active Materials

-

Battery Cell/Packs

Mining

Material processing

- Nickel

- Lithium

- Cobalt

- Aluminium

Lithium Processing

Spodumene concentrate ore is converted into either Lithium Carbonate or Lithium Hydroxide for use as an essential component to make Lithium-Ion Batteries.

Lithium-Ion batteries have strict purity requirements for the materials used in their manufacture. Impurities can lead to poor charging performance including reduced vehicle range of operation, more frequent need to charge, problems with batteries starting at colder temperature and in some extreme cases to the batteries catching on fire.

Improved filtration and separation can play an important role in improving both the process reliability for producing consistent high purity products and also for improving the product yields, reducing product re-work, and reducing operation costs.

Chemicals

Specialty Chemicals

Polymers

- Separator

- Electrolyte

- Anode/Cathode

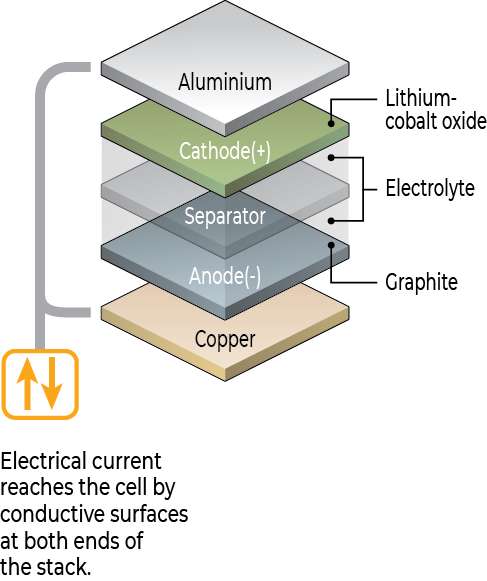

The cathode or positive electrode is made of a very pure mix of metal oxides containing lithium. The more uniform its chemical composition and crystal structure, the better battery performance and life is.

To meet the EV battery manufacturers’ specifications, high performance filtration solutions are required at the different fabrication stages to produce pure and uniform cathode active materials.

To learn more download our Case Studies and see how Pall have provided the purity of active materials required

Chemicals

Micro-Electronics

Automotive

- Casing

- Filling

- Slurry

- Cleanliness Monitoring

Component Cleanliness is an important parameter monitored in the EV battery industry as it directly impacts the performance of the battery cells themselves, especially their capacitance and thermostability performance.

It is essential to clean the battery casing before the final assembly of the cells but equally to ensure that any residual water or solvents used in the cleaning process is removed. A consistent method to determine component cleanliness is achieved using Pall’s PCC Cleanliness Cabinets

For more information and to find the right solution for your Lithium-ion battery, please contact one of our regional experts on the form provided.