Estimated hold-up volumes of T-Series TFF Cassettes with Omega™ Membrane ”(Pall™ Life Sciences products)

| Cassette format | Area (m2) | Estimated hold-up volume per cassette (mL) | Hold-up volume per SS holder (mL) | SS holder type |

|---|---|---|---|---|

| T01 | 0.0093 | 3 | 2 | Centramate™ LV |

| T02 | 0.0186 | 6 | 2 | Centramate™ LV |

| T12 | 0.1 | 30 | 10 | Centramate™ |

| T06 | 0.5 | 150 | 100 | Centrasette™ |

| T26 | 2.5 | 750 | 100 | Centrasette™ |

Note that it is imperative to determine the total hold-up volume for the tangential flow filtration (TFF, also called cross-flow filtration) system following installation of cassettes. Most of it is recoverable, it contains the cassette, holder, and the feed/retentate flow path. This is described in the User Guide USTR 2433b – page 18 - § 3.3 Hold-up Volume and Minimum Working Volume

No. The membrane MWCO cannot be verified by the cassette integrity test. The cassette integrity test cannot differentiate between a 10 kDa and 100 kDa membrane. The membrane MWCO is verified by the solute passage test. The membrane integrity test confirms if the cassette has been installed properly into the cassette holder, the torque has been applied sufficiently to activate the external seals, and there are no gross leaks on the membrane.

Reference product pages:

The following description it is not intended as an instruction for use, but rather a summary on the test. Refer to section 4.6, page 31 System and Membrane Cassette Integrity Test of the T-series Cassette Care and Use Procedure USTR 2433b for detailed instructions.

This integrity test method is recommended for an ultrafiltration membrane with a molecular weight cutoff (MWCO) of ≤ 300 kDa.

General procedure

- The cassette should be fully wetted out with water prior to conducting the integrity test. A clean compressed air source should be connected to the feed line, with an isolation valve between the pump and the air inlet line. The compressed air source requires a regulator that can be controlled to the recommended test pressure with a mass flow meter installed in the air line upstream of the filter. Alternatively, an integrity test instrument can be used if it can measure the required diffusive flow.

- Ensure that the system is fully drained. Set the pressure on the regulator or integrity test instrument to the specified test pressure for the specific membrane being used. The retentate valve and the isolation valve between the pump and air inlet should be completely closed, with the permeate valve completely open.

- Turn on the air supply to slowly (~ 15 to 30 s), pressurize the system to the recommended test pressure. The diffusive flow rate will initially increase before it drops and levels off at a stable flow rate. If the stable flow rate is below the maximum allowable value for the membrane being tested, the integrity test is deemed to have a passing result. If the stable flow rate value is greater than the maximum allowable value, then the test should be repeated with the permeate valve closed. This will test the system for any leaks and will help determine if the failure is due to a system leak versus a nonintegral membrane. When testing the system for external leaks, the diffusive flow rate should be < 5 standard cubic centimeters/min (sccm). It may take 15 min or longer for the flow rate to stabilize to this point on some systems, as the permeate side of the system is relying on diffusive flow through the membrane to pressurize.

Diffusive flow-rate measurement

To measure the diffusive flow, the use of an integrity test instrument or a flowmeter are recommended. If these instruments are not available, use the following procedure:

- For a large-scale system, when maximum measurable diffusive flow rate for the integrity test instrument is higher than the allowable limit, it may be possible to perform the test using a pressure decay value. This value is calculated from a formula that transforms the diffusive flow-rate limit to a pressure decay limit. To obtain pressure decay limits for your assembly, please contact Cytiva.

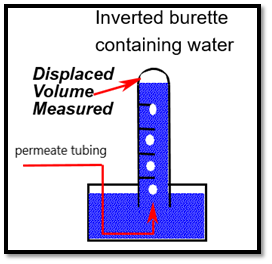

- For small, bench-scale systems, when the diffusive flow rate is ≤ 100 cubic centimeters (cc)/min, it is possible to measure the flow manually by measuring the volume displaced when the permeate line is placed into an inverted graduated burette in a beaker with water (refer to Fig 1). The volume of air displaced versus time will indicate the diffusive flow rate. With this method, it is best practice to take multiple measurements to confirm the integrity of the system.

Fig 1. Scheme for manual flow rate measurement.

How to calculate the flow-rate limit

The test limit should be calculated from the data in Table 1.

Table 1. Integrity test parameters

| Membrane MWCO | Test pressure | Rate per unit area of membrane |

|---|---|---|

| ≤ 300 kDa | 2.0 barg (0.2 MPa, 29 psig) | ≤ 1600 sccm/m2 (≤ 150 sccm/ft2) |

Example: for a 10 kDa cassette with 1.5 m2 of membrane area, the calculation is the following:

1600 sccm/m2 × 1.5 m2 = 2400 sccm, where 1 sccm is a standard cubic centimeters per minute, so the final result is ≤ 2400 mL/min.

The test should be performed at 2.0 barg (0.2 MPa, 29 psig) and the test limit is ≤ 2400 mL/min.

No. The preassembled Cadence™ Single-Use Tangential Flow Filtration (TFF) Modules (Pall™ Life Sciences products) are only available for 10 kDa, 30 kDa, and 100 kDa Omega membranes. The 300 kDa membrane is not a standard offering. If other molecular weight cutoffs are required, the end-user can evaluate the customized SUTFF module. In the customized SUTFF assembly, standard cassette MWCOs are offered and the module endplates and/or the flow distribution plates come separately. The end-user can assemble the SUTFF module on site.

Cadence™ Single-Use Tangential Flow Filtration (SUTFF) Modules (Pall™ Life Sciences products) are intended for single-use applications only. There is no claim for reusing the single-use TFF (SUTFF) module. There is no cleaning and storage study for the SUTFF modules.

Cadence™ Single-Use Tangential Flow Filtration (SUTFF) Modules (Pall™ Life Sciences products) require a SUTFF module holder, which is different from the Centramate™ or Centrasette™ cassette holder. Refer to FAQ: What is the part number of the SUTFF module holder? The Centramate™ and Centrasette™ cassette holders have built-in ports for feed, retentate, and permeate. In SUTFF, these ports are located on one of the SUTFF module endplates, and there are no ports on the module holder.

Yes, Cadence™ Single-Use Tangential Flow Filtration (SUTFF) Modules (Pall™ Life Sciences products) require a SUTFF module holder. The SUTFF module must be placed in the module holder and compressed to activate the seals. The SUTFF module will leak if it is used without a module holder. Refer to FAQ: What is the part number of the SUTFF module holder?

Cadence™ Single-Use Tangential Flow Filtration (SUTFF) Modules (P/N: CSUMxxxTxxx) have a fixed membrane area. The customized SUTFF modules may have more than one cassette installed. The total membrane area can be calculated by multiplying the membrane area of each cassette by the total number of cassettes installed.

Forward Flow integrity specification for the preassembled single-use TFF (SUTFF) modules with T-series Omega™ membrane is ≤ 1600 sccm/m2 (150 sccm/ft2) at 2.0 barg (0.2 MPa, 29 psig) test pressure. The unit sccm means standard cubic centimeters per minute.

To calculate the maximum allowable air flow rate, multiply the total membrane area in the cassette holder by the forward flow integrity specification. For example, four Omega™ OS030T06 cassettes are installed in the customized SUTFF module holder. The total membrane area is 2.0 m2. The maximum allowable air flow rate is 3200 sccm or 3200 mL/min.

Airflow rate = (membrane area) × (number of cassettes) × (integrity specification)

Airflow rate = (0.5 m2) × (4) × (1600 sccm/m2) = 3200 sccm

Please refer to Pall Publication:

USTR2896 Instructions For Use - “Cadence™ Single-Use Tangential Flow Filtration (TFF) Modules with Omega™ Membrane”

The following Cadence™ Single-Use Tangential Flow Filtration (TFF) Modules are available:

| Holder part number | Installation orientation | Module format |

|---|---|---|

| CSUH040 | Vertical | CSUMxxxT001 |

| CSUMxxxT002 | ||

| CSUMxxxT010 | ||

| CSUH250SA | Horizontal | CSUMxxxT050 |

| CSUMxxxT250 | ||

| CSUH250 | Vertical | CSUH250 |

| CSUMxxxT250 | ||

| CSUH750 | Vertical | CSUH250 |

| CSUMxxxT250 | ||

| CSUH1000 | Vertical | CSUH250 |

| CSUMxxxT250 |

No. There is no sterility claim on our Cadence™ Single-Use Tangential Flow Filtration (TFF) Modules (Pall™ Life Sciences products). The single-use TFF (SUTFF) modules are gamma-irradiated to reduce the bioburden and to be able to use water as the storage solution. The SUTFF module needs to be sanitized during the pre-use conditioning step.

| Holder type holders | Number of bolts on holder | Recommended torque range for manual torque | |

|---|---|---|---|

| in.-lbs | N m | ||

| CSUH040 | 2 | 80-100 | 9-11 |

| CSUH250 | 2 | 700-1100 | 80-125 |

| CSU250SA | 4 | 350-550 | 40-60 |

| CSUH750 | 2 | 700-1100 | 80-125 |

| CSUH100 | 2 | 700-1100 | 80-125 |

Product page Cadence™ Single-Use Tangential Flow Filtration (TFF) Modules

CY35199