Sample and mobile phase filtration are simple, economical practices that serve to extend the life of consumable HPLC parts, decrease system wear and tear, and preserve the integrity of the HPLC system.

Serious problems when operating a HPLC system can be avoided by performing routine maintenance. Most HPLC part replacement tasks, such as changing pump seals, are readily recognized as necessary maintenance; however, mobile phase and sample filtration are also maintenance practices. Routine sample and mobile phase filtration are simple, inexpensive, and convenient ways to decrease HPLC problems.

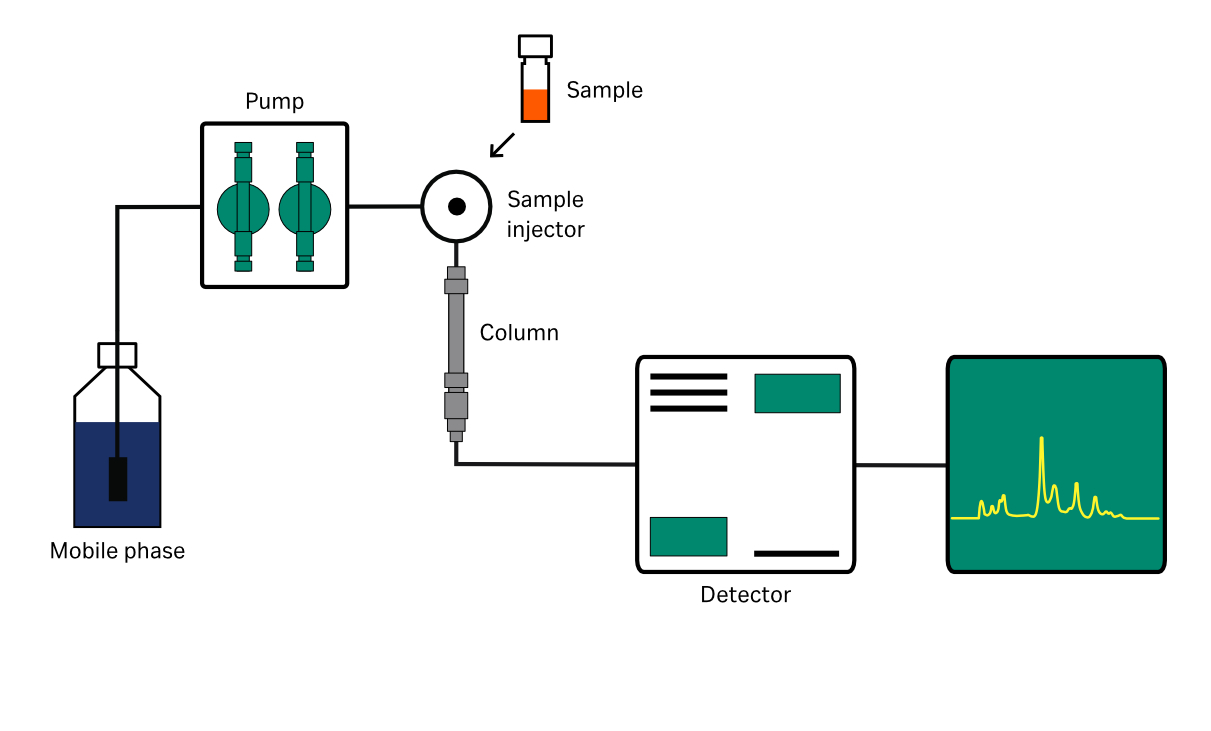

Regardless of the technical intricacies and cost of the system chosen, all HPLC systems have the same basic components, indicated in Figure 1. A basic HPLC system consists of a solvent reservoir, pump, injector, column, detector, and data recording system. Particles and microbial growth that are not removed by filtration interfere with nearly every system component.

Fig 1. A typical HPLC system.

The solvent reservoir traditionally includes an inert container, vented cap, PTFE solvent inlet line, and a 10 μm gross inlet sinker frit. The solvent reservoir is generally equipped to degas solvents by removing dissolved air. Frequent mobile phase degassing reduces erratic pump delivery of the solvent due to pressure fluctuations, and hence reduces detector noise. Degassing removes dissolved oxygen that can result in oxidative degradation of the sample and mobile phases, which reduces the sensitivity and operating stability of ultraviolet, refractive index, electrochemical and fluorescence detectors.

By filtering the mobile phase, analysts can reduce debris capable of plugging the sinker and column frits, causing contamination, damaging pump valves, blocking capillaries, causing poor peak performance, and contributing to extra peaks and excessive chromatographic noise.

Mobile phase filtration is performed prior to placing the solvent into the solvent reservoir. Buffered mobile phase solvents require daily filtration with a 0.2 μm filter to eliminate microbial growth that could increase the baseline.

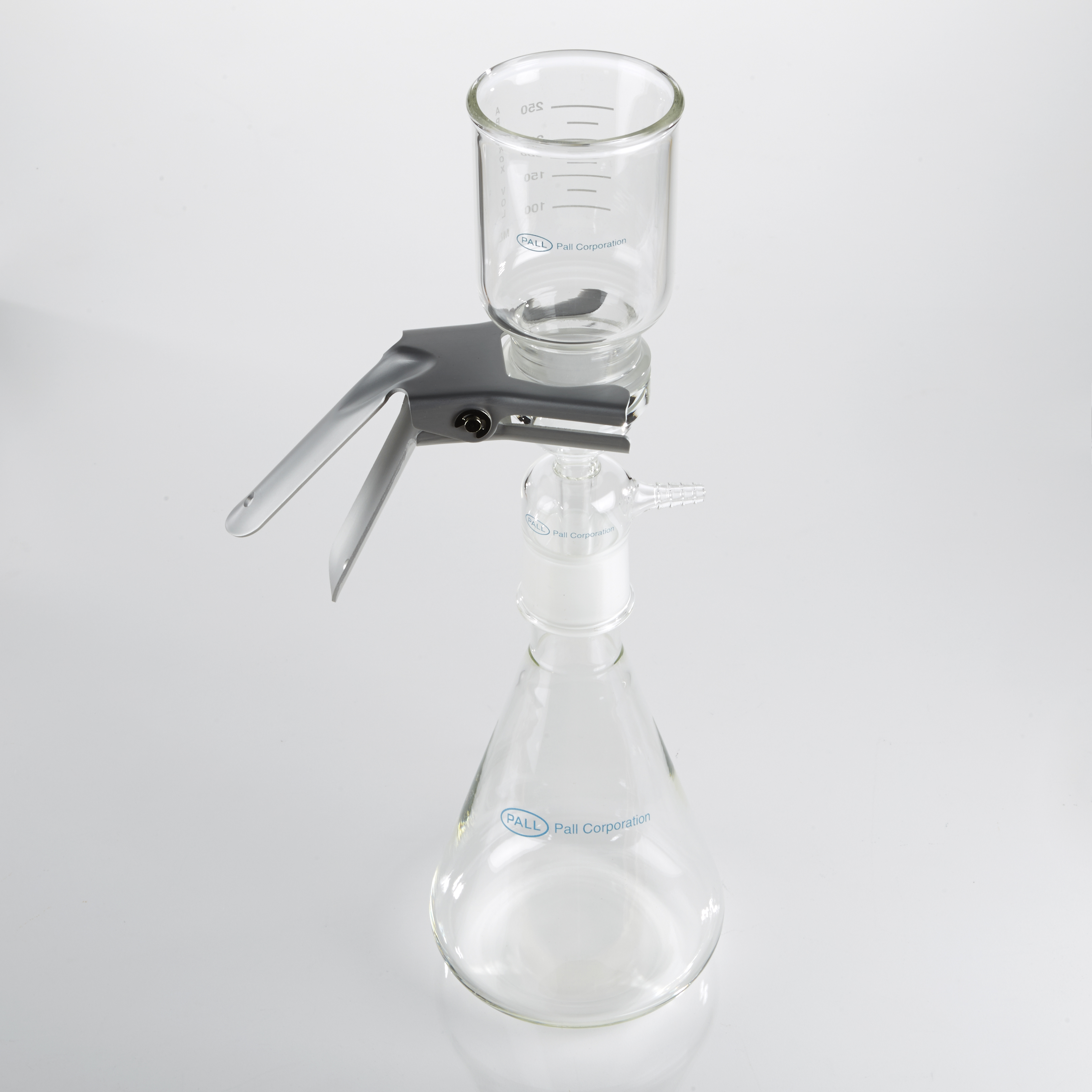

A typical solvent filtration apparatus is depicted in Figure 2. These traditional filtration systems can sometimes be challenging to manipulate within the laboratory, and as they are constructed from glass they can easily be broken. Contamination concerns from the filtration apparatus may also deter many analysts from filtering solvents. By dedicating a reservoir to each solvent, and frequently changing and cleaning the reservoir bottle and sinker frit, contamination problems are reduced.

Fig 2. Traditional glass filtration apparatus.

All filtration should be performed prior to placing the mobile phase in the solvent reservoir. Most typically, a glass filter funnel and flask assembly is used. However, this requires each reservoir to have a dedicated funnel and flask to eliminate cross-contamination. The solvent bottle itself must also be lifted high above the lab bench to fill the top of the funnel assembly, creating a potential health and safety hazard.

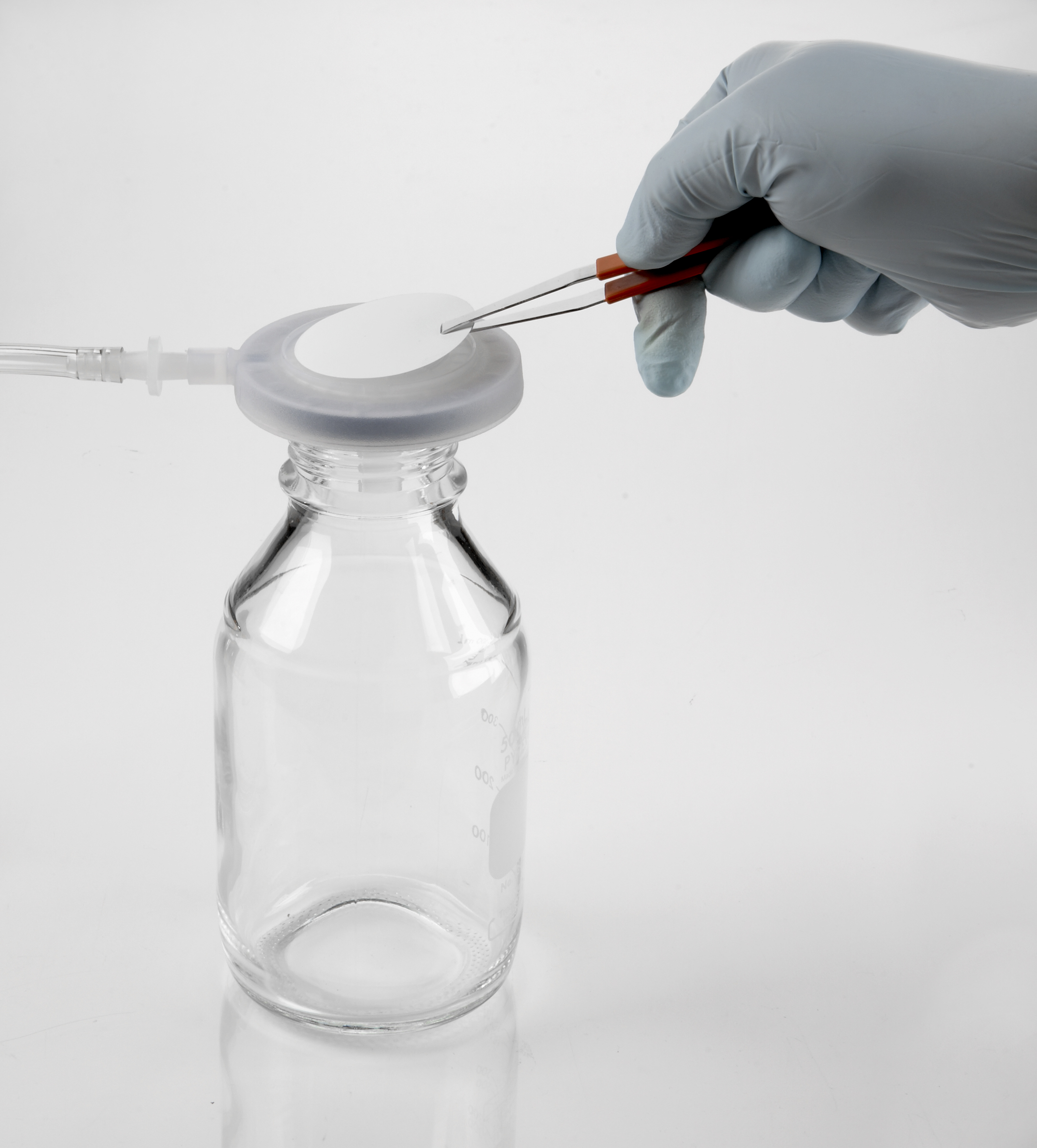

These concerns can be alleviated using the SolVac™ filter holder (a Pall™ Life Sciences product), which fits directly onto the top of the solvent reservoir, for example a vacuum-proof solvent bottle. The SolVac device depicted in Figure 3 eliminates the need to have dedicated filtration apparatuses by minimizing cross-contamination when filtering multiple solvents.

SolVac devices also help prevent the hazards associated with elevating solvent bottles high above the lab bench. Using the SolVac device eliminates the need to continually pour and wait for the sample to filter, continually refilling the funnel as space allows, thus reducing the likelihood of spilling aggressive solvents compared to glass funnels or disposable cup systems.

Fig 3. SolVac™ filter holder and membrane discs.

The SolVac filter holder features a patented magnetic seal that allows for easy handling and placement of membrane discs, reducing the risk of membrane tearing compared with screw and clamp fit devices.

With a chemically resistant and polypropylene construction, resistant to common HPLC mobile phase solvents such as methanol, acetonitrile, and tetrahydrofuran, the filter holder accepts 47 mm disc filters. In addition, the durable plastic construction means the device will not shatter if accidentally dropped, which can occur with glass funnels, assemblies, or pick-up adaptors.

Shop for filter holders.

SolVac™ filter holder operation

Step 1

Place base on the receiving vessel with gasket seal seated on the rim of the vessel. Attach vacuum tubing from vacuum source to the vacuum port adaptor located on the side of the housing base. Place the membrane on the clean, dry filter support.

Step 2

Attach inlet feedline tubing to the tapered inlet on the upper housing. Place upper housing onto housing base to securely seal the membrane. Place feedline tubing into solvent to be filtered.

Step 3

Apply vacuum while firmly holding the SolVac filter housing until full vacuum is drawn. When the required vacuum is achieved and the system is “charged,” open the thumb clamp to start the filtration. Continue to filter until all of the solvent is drawn through or the receiving vessel is full.

Membrane selection

A major concern when choosing a solvent filter is solvent compatibility with the filter material. Choosing the proper filter requires knowledge of filter/solvent compatibility and the chemical/physical characteristics of the filter. These characteristics include pore size, extractables, hydrophobic/hydrophilic character, and binding properties. Typically for HPLC applications a 0.45 μm pore size filter is selected, while for bacterial removal or UHPLC applications a 0.2 μm filter is chosen.

Cytiva supplies a wide selection of 47 mm membrane filter discs, including our wwPTFE membrane discs, which are chemically compatible with the majority of common laboratory HLPC solvents, thus simplifying filter selection.

Download Critical for analytical eBook.