Microorganisms can halt the production of pharmaceuticals, spoil food, ruin the taste of beverages, and potentially cause illness. Contamination events can have severe consequence for manufacturers, impacting their brand and reputation and affecting manufacturing supply chains, resulting in lost business and potential penalties.

So, the accurate and reliable detection and identification of microbiological organisms is critical to ensure that manufacturers can supply high-quality and safe products to their customers.

The Membrane Filter (MF) technique is an effective and accepted technique for testing fluid samples for microbiological contamination. The technique was introduced in the late 1950s as an alternative to the Most Probable Number (MPN) procedure for the microbiological analysis of water samples. The MF technique offers the advantage of isolating discrete colonies of bacteria, whereas the MPN procedure only indicates the presence or absence of an approximate number or organisms (indicated by turbidity in test tubes).

This membrane filtration method was accepted by the U.S. EPA for microbiological testing of potable water in the 11th edition of Standard Methods for the Examination of Water and Wastewater. In the 1978 publication, Microbiological Methods for Monitoring the Environment, the U.S. EPA stated that the MF technique is preferred for water testing because it permits analysis of larger samples in less time.

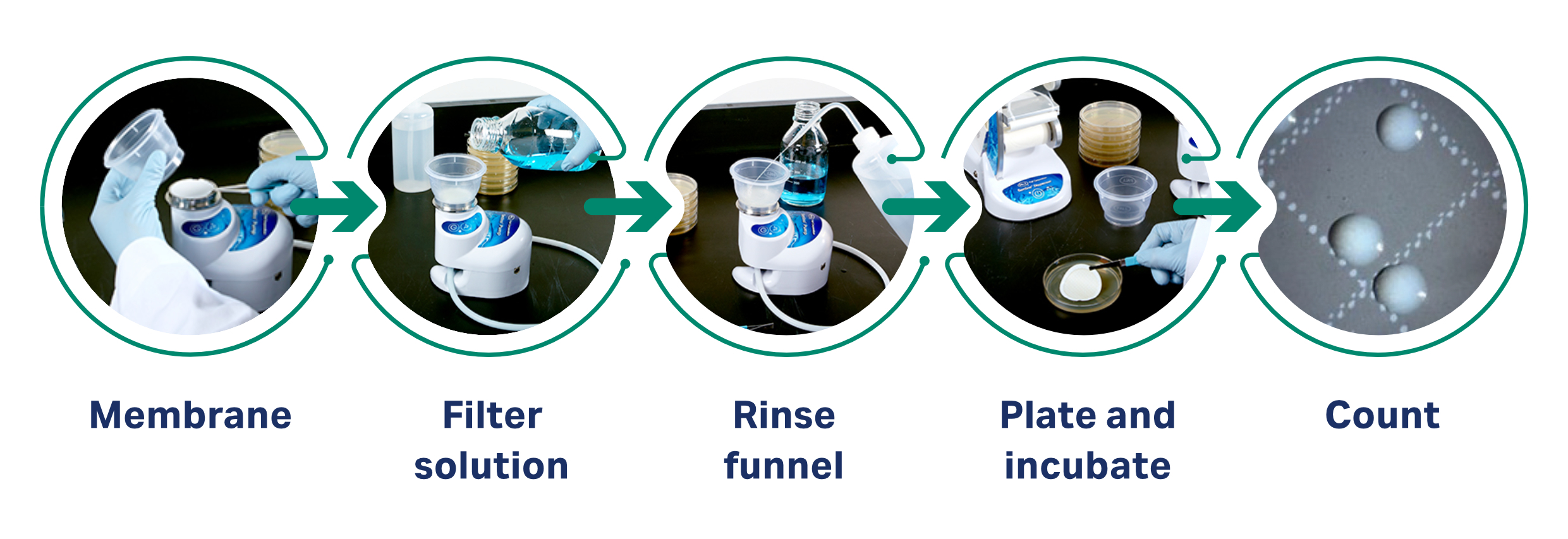

The method follows some very simple steps as can be seen in Figure 1. The sample is poured onto a filter membrane, usually inside a funnel, and then filtered through. The funnel is then rinsed, and the membrane filter placed on a culture medium for culture and analysis.

Fig 1. The Membrane Filter technique.

The choice of membrane pore size can be made based on the type of organism or group of organisms that are to be detected. The membrane filter features gridlines that aid in the counting of colonies. It is important that these gridlines do not impact or inhibit growth.

Advantages of the Membrane Filter technique:

- Permits testing of large sample volumes.

- Reduces preparation time as compared to many traditional methods.

- Allows isolation and enumeration of discrete colonies of bacteria.

- Provides presence or absence information within 24 hours.

- Effective and acceptable technique. Used to monitor drinking water in government laboratories.

- Useful for bacterial monitoring in the pharmaceutical, cosmetics, electronics, and food and beverage industries.

- Allows for removal of bacteriostatic or cidal agents that would not be removed in Pour Plate, Spread Plate, or MPN techniques.

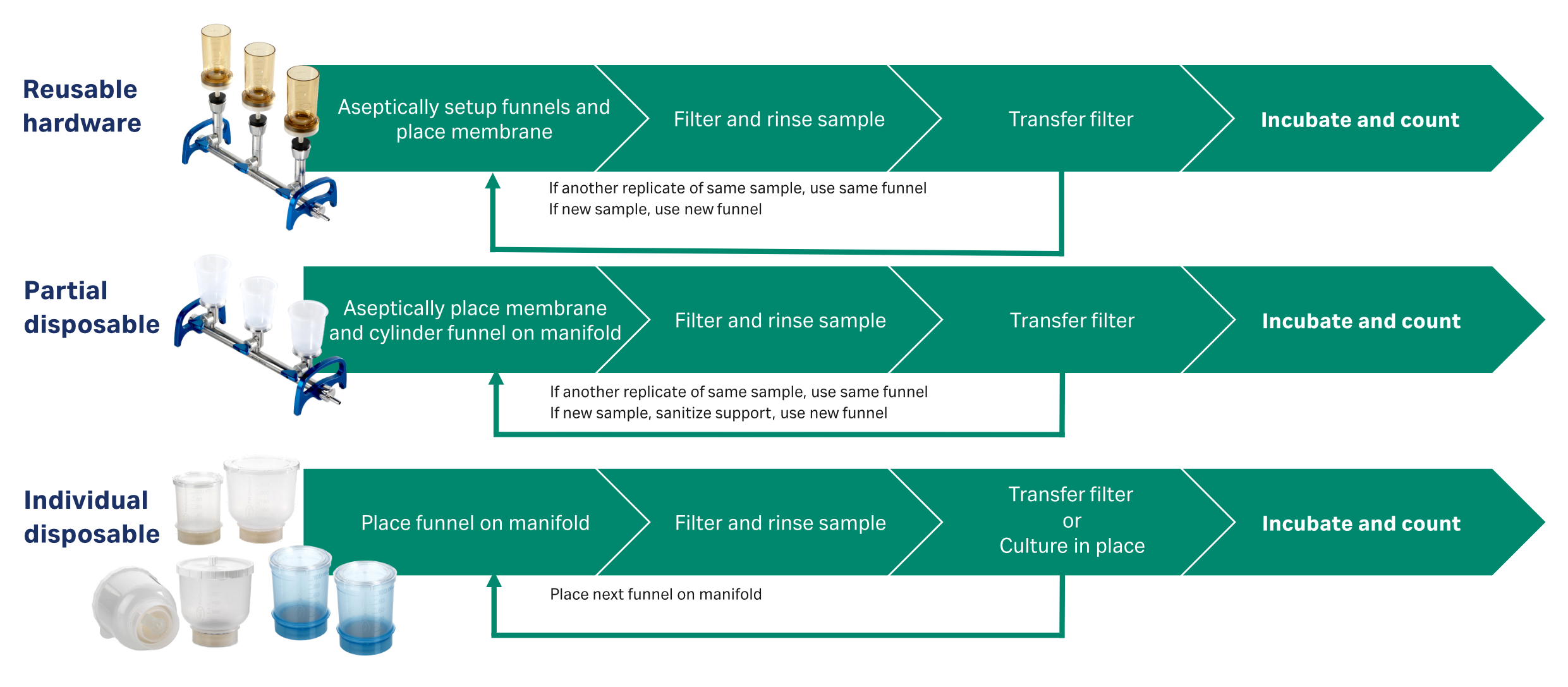

The MF technique can be performed in the laboratory be utilizing different products and workflow approaches as shown in Figure 2.

Fig 2. MF technique workflow examples.

The choice of workflow approach adopted by microbiologists can be based on several factors including product handling preferences, laboratory efficiency, cost per test, recovery of organisms, and controlling sample to sample cross-contamination.

The MF technique can be performed by using reusable hardware. A membrane disc is placed into a reusable funnel that has been previously autoclaved, the sample filtered, and the membrane transferred to a petri dish. If another replicate of the same sample is required, then the same funnel might be reused. When moving to a new sample a newly autoclaved funnel should be used to prevent sample to sample contamination.

A partially disposable workflow uses a presterilized cylinder funnel. The funnel and membrane disc are aseptically placed onto a manifold, the sample filtered, and the membrane transferred to a petri dish. If another replicate of the same sample is required, then the same cylinder funnel may be reused. The cylinder funnel is discarded after use. When moving to a new sample a new cylinder funnel should be used, and the manifold support sanitized. This workflow allows users to rapidly process multiple samples with a reduced amount of laboratory preparation time

Microbiologists may also perform the MF technique by using individual disposable funnels. The funnels contain an encapsulated membrane and are purchased presterilized. The funnel can be placed directly onto a manifold system and the sample poured directly into the funnel. The sample is filtered and then the membrane transferred to a petri dish. This workflow reduces the amount of laboratory preparation required, and the use of individual disposable funnels can greatly reduce the potential for cross-contamination from sample to sample to occur.

Product handling can have an impact on both laboratory efficiency and cross-contamination control; however, the ergonomics of product use can also have an impact on the day-to-day wellbeing of analysts, especially in busy laboratories that process numerous samples on a daily basis.

The repetitive nature of routine laboratory work puts microbiologists at risk for repetitive strain injuries (RSI). Routine activities often include repeating the same movements over and over, which can take a toll on hands, wrists, and shoulders and can lead to serious injury. RSI can lead to laboratory user fatigue and variability that causes poor technique, errors, and increased cross-contamination. In a microbiology laboratory, there are many ways to avoid manual labor stress by working in a more ergonomic manner.

Our high-performance membranes, filter funnels, manifolds, pumps, and accessories are designed for simple operation, ease-of-analysis, and minimized contamination risk to produce reliable test results. We supply a range of microbiology products that are designed for different users’ workflow requirements whether working in pharmaceutical, food and beverage, or municipal water testing.

Learn more about our microbiology products: download our Micro QC interactive brochure.