Blog

Point-of-Use Water Technology

What is the Technology Inside a Point-of-Use Water Filter?

2021년 2월 1일

POU(Point-of-Use) 물 여과의 기본 사항에 대해 자세히 알아보려면 ‘What is a Point-of-Use Water Filter’ 블로그 문서를 참조하세요.

Point-of-use (POU) water filters are designed to reduce or remove waterborne pathogens from the water distribution system. However, there are different point-of-use water technologies available to do this. In this case, different technologies often mean different performance and different results.

Types of Technology: Membrane vs. Hollow Fibers

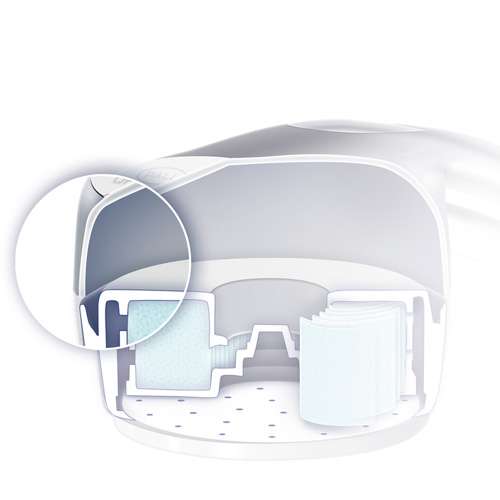

Membrane POU water filters are often made of a pleated media membrane in which the stated pore size is uniform throughout. For example, if the filter claims to be a sterilizing-grade filter at 0.2 microns, this means that all water flowing through the membrane of the filter must flow through these 0.2 micron pores.

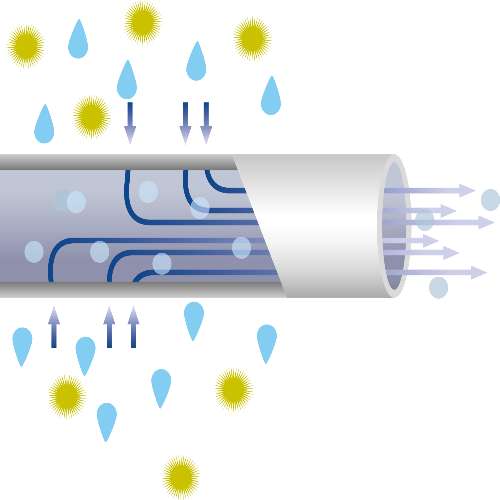

Hollow fiber POU filters are made of long, hollow tubes, much like a straw. These tubes have pores in their walls and the water typically passes from outside to inside the tubes.

Both technologies retain pathogens through physical filtration. Since there is no chemical component, these filters will not remove chlorine, chemicals, or minerals from the water.

How Do They Perform

In use, both filters can reduce waterborne pathogen risks. They also both might feature prefiltration of some sort to remove larger particles and allow for longer filter life.

Membrane filters will often incorporate double-layer sterilizing-grade filter membranes, meaning when subjected to the ASTM F838 bacterial test, the filter must demonstrate complete retention of the challenge organism. In use, this is an advantage because it allows for the highest-degree of prevention at its outlet. However, membrane filters are more prone to filter blockage or reduced flow over time. This is because the filter removes all particles at and larger than its stated pore size. In areas with high-particulate, this may mean reduced filter life due to low flow.

Hollow fiber filtration, when subjected to ASTM F838, may result in a log reduction of the challenge organism and thus would be considered a microbial filter. In use, this means the filter may reduce waterborne pathogens at the outlet but may not completely retain them all. Hollow fiber tubes are a single layer of filtration and, due to their flexibility and the possibility of mechanical defects, may also be more prone to breakage when subject to high particulate or other stresses. In the case of breakage, there would be nothing obvious to indicate that the filter was not performing as intended. The hollow fibers also typically incorporate a 2-part epoxy resin to secure the fibers to the housing. This resin can be a nutrition source for microbes and can be weakened in thermal cycling.

The two technologies have been compared for performance in research published by Totaro et al. in 20171. In this study, a membrane faucet filter (filter C) was compared to a hollow fiber faucet filter (filter A) and a hollow fiber shower filter (filter B). The study found that: “There was a high capacity of microbial retention from filter C; filter B released only low Brevundimonas spp. counts; filter A showed poor retention of both [tested] microorganisms. [i.e. Pseudomonas aeruginosa and Brevundimonas diminuta]”

How to Choose

Ask yourself the following questions when considering POU water filtration: What type of patients are being cared for in this unit? Is there an ongoing concern about waterborne pathogens in the building? What do I know about my water quality?

It is also important to think critically about micron size. For example, when considering a 0.2 micron hollow fiber and 0.2 micron membrane filter, they may have different results during the ASTM F838 test and in use. Also, if a filter is rated lower than 0.2 microns, it does not necessarily indicate better performance, and could even be more prone to clogging. Thus, it is important to consider micron size, ASTM F838 results for both membrane and hollow fiber, and your facility when choosing filter technology.

References

- M. Totaro et al., Experimental comparison of point-of-use filters for drinking water ultrafiltration, Journal of Hospital Infection, 96 (2), 2017, p. 172-176, https://doi.org/10.1016/j.jhin.2016.11.017.

감사합니다

Thank you for your interest. We will be in touch soon.

Marissa Khoukaz - Business Development Manager — Hospital Water

- Medical Industries

- Author

- Sort By