Challenges in Flavor Production

While adjusting to the latest consumer trends is key, flavor houses must also meet requirements for clarity and purity. Selection of the right filtration technology is critical in achieving these goals, as flavor producers must overcome multiple challenges:

- Flavor substances can require complex processes due to variability in raw materials, extraction methods, and solvents used.

- Mixing different solvents and water can cause turbidity-forming colloids, which may lead to haze after packaging.

- Existing opacity/turbidity can be complex and of different origins. Waxes in oils, for example, in citrus flavors, can stress separation processes.

- Aroma and color are delicate chemical components. Manufacturing techniques must provide a delicate balance in preserving the fragile notes while delivering clarity.

- Flavor production requires great flexibility to process large and small batches.

Filtration and separation equipment used in flavor production must be selective and have the flexibility to remove the different sources of turbidity reliably. However, it is also essential that these steps do not negatively influence or reduce quality-enhancing characteristics like Aroma and color.

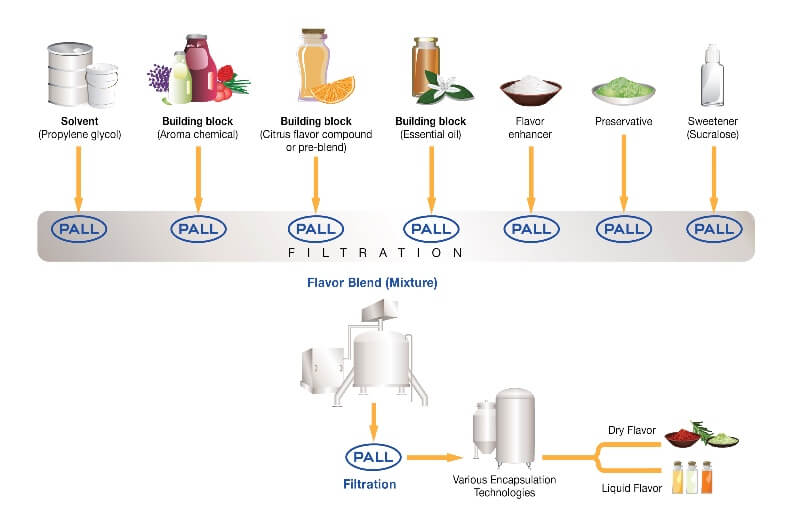

As illustrated below, various filtration methods are used during flavor production to achieve specific goals.

Particle removal

Particle filtration is usually the starting point for clarifying liquid flavors. This step aims to remove coarse and fine particles that typically tend to settle and form a sediment layer at the bottom of blend tanks or float to the surface of the flavor. Effective solutions for particle removal include using a coarse filter.

Removal of colloidal haze

The requirement to mix different solvents, alcohol and water significantly impacts the solubilities of turbidity-forming colloids. A chill filtration step can force the particles to form to remove colloidal haze. Technologies combining filtration and adsorption can then successfully remove colloidal haze at the best economic efficiency, helping to reduce the risk of precipitations that might occur after packaging. Depth filter sheet-based products are typical in this step. However, Pall SUPRApak™ depth filter modules provide a more effective removal through adsorption.

Wax and lipid removal

Naturally occurring waxes that originate in the citrus peels are solubilized during extraction. Cloudiness upon precipitation is a potential effect that can lead to a decrease in quality. There are a variety of methods to separate the wax solids, but these pose challenges. Drawbacks in standard processes include poor final product quality, process flow rates are often low, or the installations require large sizing. Replacing the disposable filters to allow batch completion can be time-consuming, labor-intensive and costly. Our flavor filtration solutions help achieve product stability and reduce processing time.

Removal of microbiological contaminants

It is recommended that filtration measures be incorporated to prevent microbiological contamination of flavor-producing raw materials. For example, there may be a need to remove TAB (Thermoacidophillic bacteria) from aroma chemicals and ingredients or yeast that may be present in binders. Pall has developed a series of depth filter sheets designed for effective removal.

Removal of water from oil-based flavors

In many cases, oil-based flavors are extracted from plants and may contain traces of water from the plant cells. A coalescing or separation step is usually necessary to remove the water to achieve a pure essential oil. Pall solutions utilize adsorption to eliminate water effectively, reducing the required contact time.