For more information on improving the efficiency of your processes, contact our team of filtration experts.

Green Hydrogen Filtration

Explore filtration solutions that enable efficient green hydrogen production. Learn how water treatment, gas separation, and drying steps help deliver high-purity hydrogen for sustainable energy applications.

Green hydrogen is hydrogen produced by splitting water using renewable electricity. It supports decarbonization goals across industries, and achieving high purity requires filtration and separation at key stages from clean feedwater to gas side aerosol removal and moisture control. Hydrogen filtration solutions play a critical role in enabling these processes, as outlined in our Hydrogen Filtration Solutions overview.

Why green hydrogen?

Hydrogen produced via electrolysis powered by renewable energy sources offers a low carbon pathway for energy, storage, and industrial feedstock applications. It supports net zero initiatives and the broader energy transition.

Why is filtration critical in green hydrogen production?

Filtration and separation are essential across all electrolyzer technologies including alkaline, PEM, and solid oxide systems, where clean feedwater and controlled gas streams support stable, efficient hydrogen generation. Similar principles also apply to blue hydrogen production, where maintaining gas purity and protecting equipment are equally important for reliable system performance.

Filtration helps to:

- Extend electrolyzer lifetime by limiting solids and particulates entering with the feedwater.

- Protect downstream equipment by preventing entrained liquids or aerosols in the product stream from impacting compressor performance.

- Safeguard end use applications by controlling fine particulates from process piping or dryer media that could compromise final hydrogen purity.

Green hydrogen purification challenges

Typical produced hydrogen can contain 2,000 to 6,000 ppm oxygen and more than 2,000 ppm water, while ISO 14687 fuel cell specs recommend 5 ppm for each. Multiple filtration, separation and drying steps are needed to reach target purity and ensure oil free gas after compression.

What filtration methods are used in green hydrogen production?

A range of filtration and separation methods are used across hydrogen production to protect assets and maintain purity. Pall’s portfolio supports several of these approaches, including:

- Mechanical and depth filtration for removal of particulates and suspended solids in both water and gas streams.

- Liquid gas coalescing filtration to eliminate aerosols and entrained liquids that can compromise compressor performance or downstream purification.

- Adsorption based drying, crucial for achieving moisture levels that meet hydrogen purity targets for compression, transport, or end use applications.

How do filtration steps support typical green hydrogen processing?

Filtration plays a key role at several stages of green hydrogen production, ensuring that both water and gas streams meet the purity requirements needed for efficient electrolysis and downstream processing. Pall’s solutions support critical steps including:

- Feedwater cleanliness, using staged particulate removal and polishing to reduce solids entering the electrolyzer and affecting stack performance.

- Gas–liquid separation, where coalescers remove entrained liquids and electrolyte aerosols after electrolysis to prevent compressor wear and instability.

- Particulate control, preventing solids from process piping or dryer media from impacting overall hydrogen quality prior to compression and storage.

- Drying, where adsorption dryers achieve low moisture levels required for hydrogen use in high purity applications.

These steps help maintain consistent hydrogen purity and ensure that production assets remain protected throughout the process.

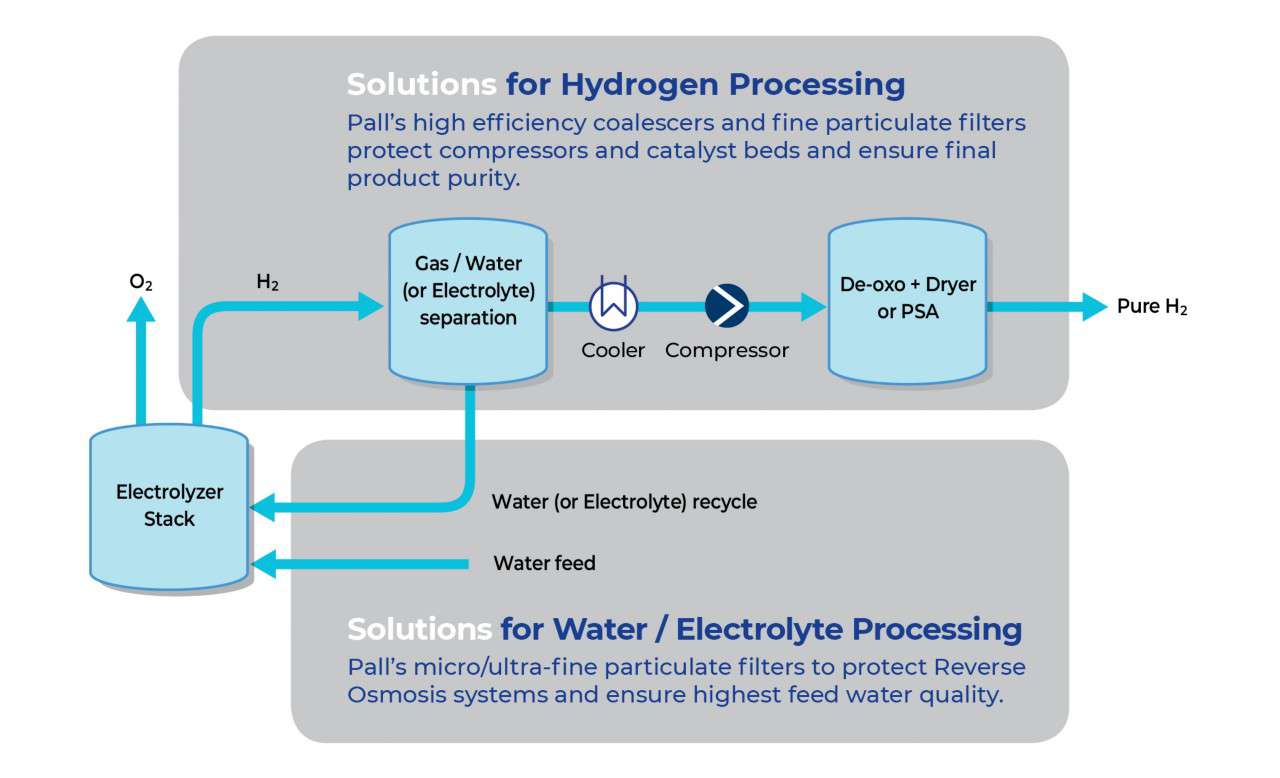

This diagram shows how Pall filtration and separation technologies support each stage of the green hydrogen production process, from clean feedwater to purified, dry hydrogen ready for compression, storage, or end use.

Typical Green Hydrogen Production process and Pall’s Solutions

Filtration Solutions for Hydrogen Systems

Pall’s filtration solutions are engineered to meet the needs of hydrogen systems across production, purification, and final use. They help:

- Optimize electrolyzer reliability by providing consistent feedwater quality.

- Enhance process efficiency through removal of aerosols and particulates that can reduce compressor or PSA performance.

- Improve system uptime and reduce maintenance, thanks to high efficiency coalescers and particulate filters designed specifically for hydrogen service.

These solutions support green, blue, and emerging hydrogen applications, helping operators meet stringent purity and reliability expectations.

Water/Electrolyte Processing:

Pall’s micro/ultra-fine particulate filters to protect reverse-osmosis systems and ensure highest feed water quality.

Frequently Asked Questions

What electrolyzer types are used for green hydrogen?

Alkaline, polymer electrolyte membrane (PEM), and solid oxide electrolyzers are currently deployed

Why are filtration and separation steps necessary?

To manage solids in feedwater, remove liquids from the hydrogen product stream, and control particulates that could impact downstream equipment or final purity

What purity targets apply to fuel cell hydrogen?

ISO 14687 fuel cell specifications are highly stringent, including low moisture and oxygen limits that necessitate multiple purification steps

What protects compressors and catalysts?

High efficiency coalescers and particulate filters help protect compressors, safeguard catalyst beds, and support final hydrogen purity

How are electrolyte aerosols addressed?

Liquid gas coalescers designed for low pressure drop and chemical compatibility efficiently remove electrolyte mists common to alkaline systems

What influences technology selection?

Selection depends on required purity, flow rate, and contaminant type. Reviews and testing help determine where to integrate each step for performance and lifecycle cost

As a global leader in filtration technology and solutions, we understand that one solution cannot fit all. Our experts will provide bespoke solutions tailored to your needs in partnership with you. To find out more, contact us.

Pall in the Press

Read our articles featured in leading titles in the industry trade press

Hydrogen Power : Why filtration is the key to a green energy future Filtration+Separation, Mar '22