Li-ion batteries play a significant factor in the world’s push to net-zero. The cathode is at the heart of lithium-ion batteries and must be in its purest form to deliver the highest possible efficiency. Manufacturers of Cathode Active Material (CAM) encounter numerous challenges due to the inclusion of various other chemicals in CAM, and the need to meet specific particle size distribution, preserve crystal structure, control surface area and porosity, and adhere to rigorous contaminant level specifications. Pall Corporation offers a comprehensive range of purification and filtration products that can assist you in optimizing your manufacturing process.

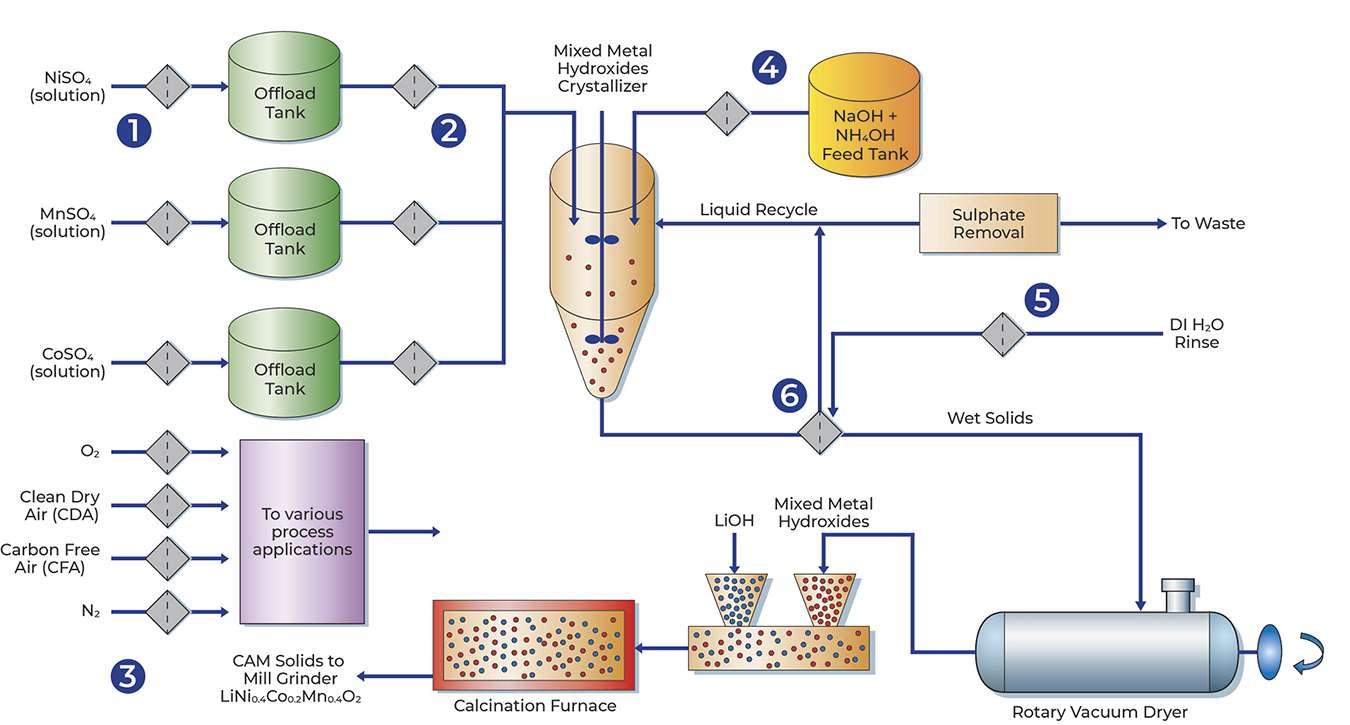

A process schematic for the CAM process shown below identifies the critical purification steps, from the raw materials, through the precursor stage, to the final CAM product.

Pall Corporation: Filtration experts in Cathode Active Material (CAM) production.

Pall technologies help CAM manufacturers enhance product purity, achieve desired crystal size, remove contaminants, enabling producers to meet cell assembly specs and increase production yields.

| No | Application | Filtration Value | Pall Product |

|---|---|---|---|

| 1 | Metal Sulfate Solutions to offload tank | Meet high purity specs for CAM Production | Poromesh® 500 um |

| 2 | Metal Sulfate Solution to Crystallizer | Meet high purity specs for CAM Production | Polyfine® II 0.5um |

| 3 | Gas Filtration (O2, CDA, CFA, N2) | Remove fine particles from gasses | Aerolith® Ceramic, Dynalloy® metal, Profile® Coreless, Emflon® (0.3 to 1 um) |

| 4 | NaOH + NH4OH | Remove undissolved salts, iron oxides and other solid contaminants | Polyfine II 0.5um |

| 5 | DI Water | Reduce dissolved metals and solid fines in CAM slurry | IonKleen®, Profile II, Emflon (0.2um to 10um |

| 6 | Collection of precipitated mixed metal hydroxides intermediate product | Meet product quality spec with higher reliabllity & higher yeild by ensuring safe work environment through automated single stage process | Pall Dia-Filtroplast |

Learn more about the solution that can support your applications or contact an expert today.