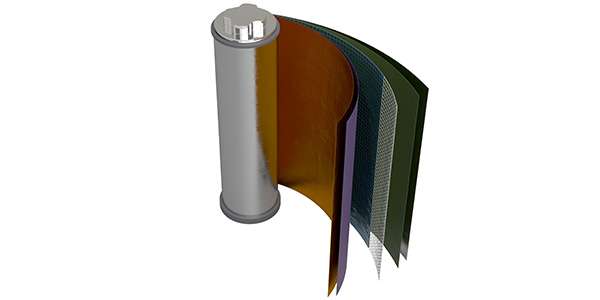

Separators play a crucial role in batteries to prevent short circuits, ensuring the safe operation of batteries. Li-ion batteries, have the highest demand in the world due to their high charging capacity, and extended battery life requirements. The separators are thin porous polymeric membranes that actually separate the positive and negative electrodes, allowing the flow of lithium ions while charging the batteries. For the separators to function optimally, it is important that the polymeric materials they are made of are filtered prior to their formation. These high-performance filtration solutions are used widely across many different fabrication processes to achieve the separators required technical specifications, cleanliness quality, and uniformity of the polymeric materials.

Pall Corporation: Experts in Separator Filtration

Pall’s proven polymer melt filter technology ensures chemical companies supply high-quality polymeric separators to EV battery manufacturers. Purification steps include filtration of the molten polymer prior to film formation and filtration of various other additives and coatings used in the process. A process schematic for the separator film production process identifying the purification steps, is shown below.

Learn more about the solution that can support your applications or contact an expert today.