The recent energy crisis resulting from the war in Ukraine has forced many European countries to re-evaluate their energy mix. Diversifying energy sources is imperative in the face of geopolitical tensions and climate change urgency. LPG (Liquid Petroleum Gas) presents a viable solution for a number of energy-intensive applications and market segments.

In order to meet the growing demand for high quality LPG on the global market, major refineries and petrochemical companies are expanding their capabilities and upgrading their existing processing plants.

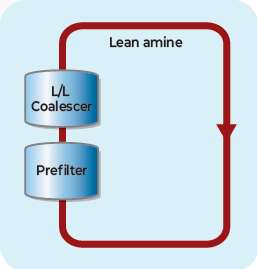

A major European refinery asked Pall to design, manufacture and install a Liquid/Liquid coalescer unit operating on its 10 tph lean amine system. Their lean amine lines had never been equipped with a coalescence system despite producing LPG for many years. Operators struggled to meet LPG specifications for hydrocarbon content (HC) of <50 ppm. To meet demand while upgrading its LPG processing lines, the plant management team agreed to rent a stand-alone filtration and separation unit from Pall, allowing time to build, install and commission the new L/L coalescence system. This meant they could keep producing LPG within the <50 ppm HC specifications while validating our final solution.

-

Challenge

-

Solution

-

Results

The process Engineering team wanted to remove free hydrocarbons from lean amines and continuously meet the < 50 ppm HC specification whatever the inlet conditions (process data monitoring was showing that amine could sometimes be subjected to high peaks of heavy HC concentration). This L/L coalescence stage is critical as the quality of lean amines directly impacts the overall LPG sweetening process. In order to obtain HC-free lean amines, Process Operators must continuously maintain the hydrocarbon content at 50ppm if possible.

Operating Conditions

Flowrate: ~10 ton/hr

Pressure: 25 bar

Temperature: 55oC

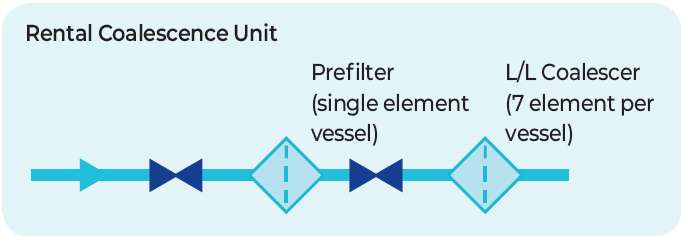

Pall and the Process Engineering team defined the location to install the rental unit on the lean amine processing line. A two-stage assembly was used to construct the rental unit:

| Function | Pall Product | Goal |

|---|---|---|

| Particulate Filtration | Ultipleat® High Flow (10μm) | Protect coalescer elements |

| Coalescing | PhaseSep® L/L Coalescer | Remove hydrocarbons from amine |

PhaseSep L/L Coalescer was selected over PhaseSep EL L/L Coalescer in order to set up the rental unit quickly.

Improved Quality, Continuous Protection, Extended Service Life

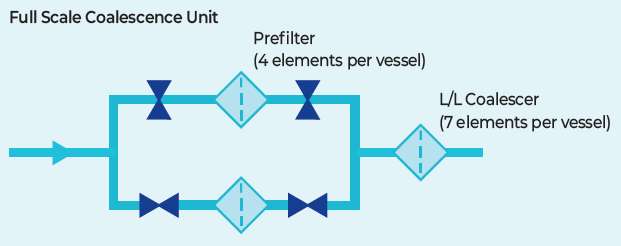

The rental unit fitted with both Pall prefilters and coalescers enabled the customer to maintain LPG production, improving the quality of its lean amine, meeting the 50 ppm HC specification. When the final coalescence system operates on the lean amine circuit (scheduled in October 2023), the overall design will be improved to not only better protect the coalescer but also reduce the OPEX budget by installing:

- A multi-element prefilter in duplex configuration to ensure a continuous protection of the L/L coalescer during element change-outs while extending the service life of the elements (larger filtration surface area)

- PhaseSep EL elements into the coalescer vessel to extend the service life of the coalescing filter elements. Based on the improvements achieved in the quality of the LPG itself since the upgrade of the lean amine system, the O&G company is planning to standardize the upgrade of 2 other processing plants using Pall PhaseSep coalescer technology.

Learn more about the solution that can support your applications or contact an expert today.