Reduza o custo e melhore o rendimento com as nossas soluções de clarificação de sidra e perry

Os nossos produtos auxiliam a remoção de levedura e sólidos da fermentação e refino

Filtração é a principal operação na produção moderna de sidra para fornecer um produto estável na prateleira e visualmente claro. Tradicionalmente, a clarificação de sidra tem sido realizada com terra diatomácea ou tecnologias de filtração à base de placas. No entanto, com uma economia mais favorável, operação mais fácil e menores volumes de resíduos, os sistemas de filtração crossflow como o sistema Oenoflow™ XL da Pall se tornaram mais amplamente adotados na última década.

Após a fermentação, geralmente a sidra tem os sólidos removidos pelo fundo do tanque e, em seguida, pode ser filtrada com agentes como bentonita, cola de peixe ou gelatina. A primeira filtração ou clarificação principal geralmente demora de 4 a 5 dias após a fermentação, mas pode ser mais demorada para produtores tradicionais ou pequenos produtores. Durante a clarificação, leveduras e outras partículas da fermentação e do refino são removidas para reduzir a turbidez e melhorar a capacidade de filtração a jusante. Historicamente, clarificação era realizada com filtros de terra diatomácea (DE), mas hoje em dia, mais e mais fábricas de sidra estão investindo em sistemas de filtração de fluxo cruzado, como o sistema Oenoflow™ XL da Pall.

Em um mercado com crescimento rápido, com produtores ampliando sua distribuição, produtores de sidra estão sob mais pressão para melhorar a qualidade e reduzir os custos, enquanto satisfazem às rigorosas exigências regulatórias e de segurança. Fabricantes de sidra são desafiados a escolher técnicas de filtração que sejam fáceis de usar, exijam menos mão de obra intensiva e sejam mais ecológicas, ao mesmo tempo que mantêm as características.

Clarificação é a principal etapa de filtração na produção de sidra para remoção de levedura e outros sólidos da fermentação e refino, visando melhorar a capacidade de filtração a jusante. Filtros tradicionais de clarificação incluem filtros de terra diatomácea (DE). Entretanto, com mais aspectos econômicos favoráveis, menor desperdício e rendimentos mais altos, os sistemas de filtração Oenoflow da Pall têm se tornado a tecnologia preferida.

Preparado para saber mais? Entre em contato para conversar com um especialista sobre a solução de filtração de sidra certa para você.

Por que diafiltração é importante?

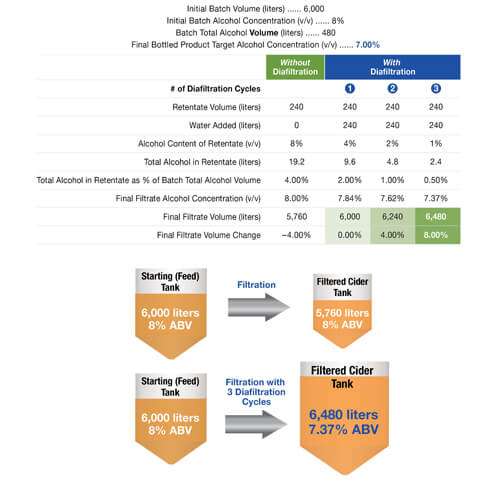

Para clientes que fermentam até concentrações de álcool mais altas e subsequentemente diluem para concentrações mais baixas na garrafa mais adiante no processo, diafiltração pode ser usada para aumentar significativamente o rendimento do produto final.

Durante a diafiltração, água é acrescentada aos sólidos finais retidos no sistema Oenoflow para recuperar o álcool que, de outro modo, seria perdido. Essa recuperação aumenta o rendimento e melhora o retorno sobre o investimento (ROI) do sistema.

Diafiltração não pode ser executada na sidra natural ou tradicional, onde o produto é fermentado somente até a concentração da garrafa porque a diluição seria inaceitável.

-

Ficha do filtro série Seitz K

Baixar:

Placas da série K

As placas de filtro de profundidade da série Seitz K foram desenvolvidas para atender a toda a gama de requisitos de remoção no setor de alimentos e bebidas.

Módulos SUPRAdisc™ II

Os módulos SUPRAdisc II eliminam os pontos fracos de construção dos lenticulares clássicos em um design de célula única usando tecnologia de separador interno-externo em um design de bloco de filtros.

Módulos SUPRApak™ Plus

O design do módulo do filtro de profundidade SUPRApak Plus PW utiliza uma nova tecnologia de vedação camada a camada.

Sistema Oenoflow™

Com a introdução da nova geração do sistema Oenoflow, a série XL, fábricas de sidra estão definindo novos padrões para alcançar qualidade, rendimento e eficiência.