Water Filtration to Meet Your Needs

Water treatment solutions to ensure process efficiency

Water is a key resource for successful food and beverage plant operation. As an ingredient, its quality can impact final product taste and appearance. Or as a utility for rinsing, cleaning and product pushing, water quality can affect the efficiency of any packaging, bottling or production facility.

Feed water content and quality can vary according to raw water source and pretreatment. Since incoming water may come from several sources including municipal water supplies, surface water, ground water, and springs, it presents many different challenges, however, the goal is the same – to provide low-SDI (silt density index) feed water for downstream processes. Selection of the right water treatment solution is key to achieving these goals.

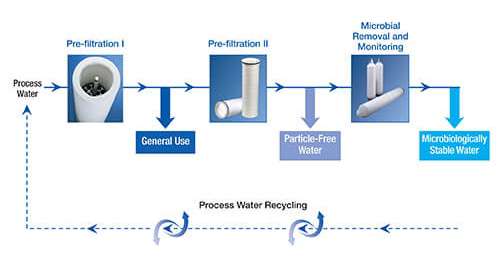

Figure below shows an example of process water filtration used within a food and beverage production facility. An initial coarse clarification step may be employed for general use water for applications including CIP and wash water, cooling water and equipment seal water. A second pre-filtration step, typically down to 1 µm might be employed to remove articles, Cryptosporidium oocyst and Giardia from water for applications like equipment sanitization water, water for cleaning of crossflow systems or wash water for fruits and vegetables. Additionally, a membrane filter could also be employed to produce microbiologically stable water used for product dilution or bottle rinsing.

Pall Aria™ systems are simple, automated membrane units designed specifically for water treatment. The systems utilize regenerable hollow fiber microfiltration membranes with a unique air scrubbing process to replace traditional water treatment filters. The system can remove virtually all of the suspended solids from surface water along with precipitated inorganics from ground water in a cost-effective, compact footprint.

Membrane filtration provides a higher clean water yield in fewer processing steps than conventional treatment and the modular design allows for expansions to match production demands. Additionally, the Pall Aria’s high solids capability enables process flexibility. Systems can be positioned at the water source, on incoming plant water, upstream of Reverse Osmosis (RO) systems to extend membrane life, or point of use for equipment rinsing and cleaning.

For applications with lower SDI values or where water quality is less variable, Pall’s “large diameter” filter solutions, Ultipleat® High Flow filters and Pall® Coreless filter elements can be adapted to individual production requirements. Replacing large mutli-round traditional cartridge filter assemblies, these filters accommodate high flow rates with simple handling and faster change-outs at low investment and operating costs.

For filter rinsing or more critical applications where sterile effluent is required, Pall offers cartridge pre-filters like the Precart PP II food industry depth filters and the

Fuente II polyethersulfone (PES) membrane water cartridge filter.

Please select the links below to learn more about each solution:

Complete the Form to Receive Future Communication

Speak to one of our filtration experts to discover how our water filtration solutions can help.