The Impact of Damage to Filling Lines and Bulk Reservoirs

Do you suffer from water in diesel fuel damage? Then use our bulk fuel filtration system. It’s efficient and made by expert professionals. That way you won’t have to worry about water in diesel fuel problems ever again. Learn more about our advanced solutions for diesel fuel filtration in bulk reservoir and filling lines.

What Happens When Water Gets In Diesel Engine?

Diesel fuel tanks are always vulnerable to water condensation. Unlike gasoline, diesel fuel, has no vapor pressure to displace air. When the tank is warm, the air expands and is forced out. Then as the tank cools at night, it sucks in humid air back into the tank. That causes the water condenses on the tank’s walls. There are many other ways water can enter fuel systems. These cause many problems – water rusts steel and iron components, loose particles of iron oxide are formed, and these can clog fuel filters. Particles may also pass though the filters to reach injectors. They can ruin surfaces and spoil fuel injection spray patterns.

This is why water removal from diesel fuel tank is so important. Our bulk diesel fuel filtration systems help combat all these issues.

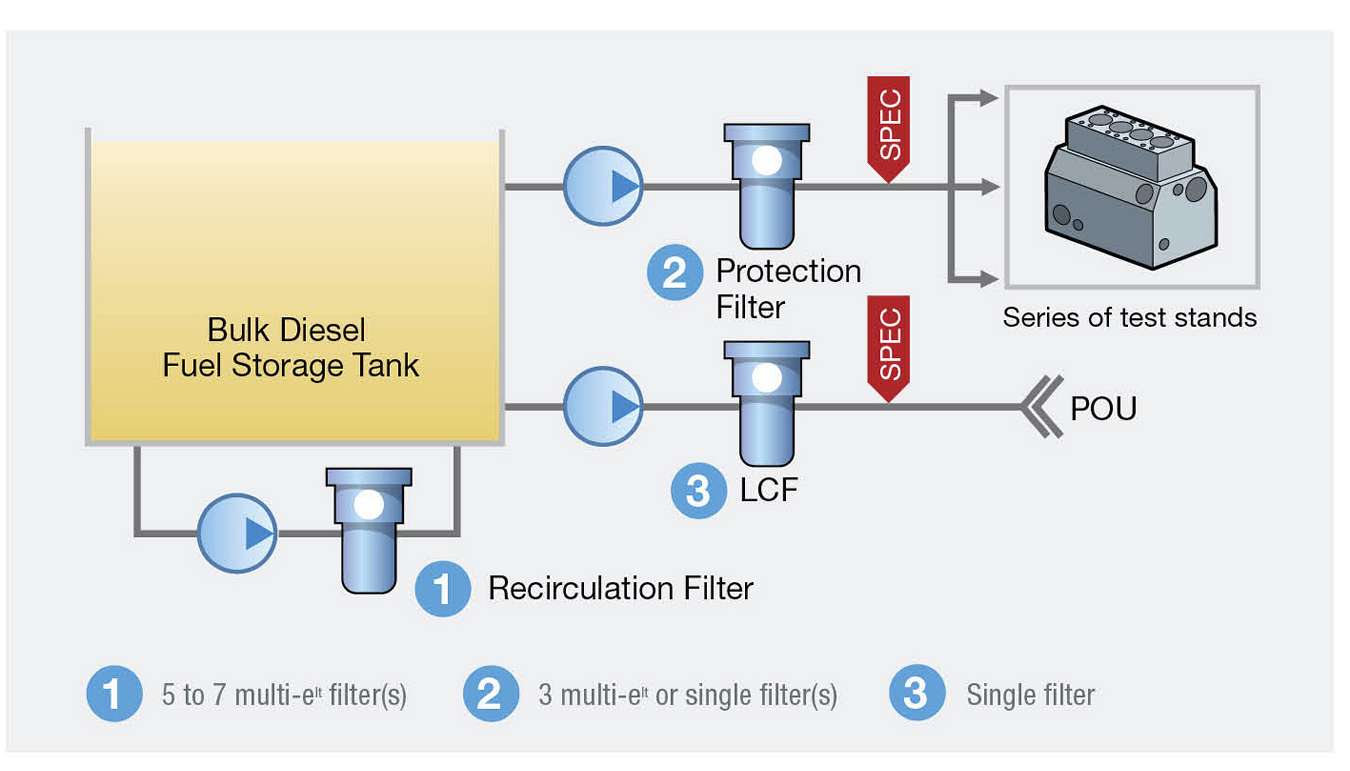

Filtration on filling lines and bulk storage systems is critical, diesel fuel must meet Cleanliness Specifications at their Points of Use. Water causes damage to both fuel tanks and engine parts. Rust and corrosion in the tank create hard particulate that is passed along in the fuel, causing engine wear. Usually, diesel bulk reservoirs contain free water which can damage the engines during the dynamic ‘Go / No Go’ performance tests. The objective is to keep the water below its saturation point so that it stays dissolved rather than entering the filling lines and the engine test stands as free water.

Innovative Particulate and Water Removal Solution

High performance filtration featuring water removal capabilities is required to protect diesel fuel engines or components like HP fuel injectors or diesel pumps. Ultipleat Diesel Plus Filters provide advanced particulate and water removal from diesel fuel within a single filter element. Perfect to combat water in diesel engine damage.

Customer benefits include:

- Low clean differential pressure across the element

- High dirt-holding capacity and long filter life

- Meets the specification for both solid and liquid contaminations

- Reduce engine/component reject rates with immediate effect in the plant

- Minimize the return of engines under warranty

- Improve the quality of the fuel available for performance tests

Beyond Ultipleat Diesel Plus Filters, many other Pall products technologies can be used. To find our more, speak to one of our specialists by contacting us on the form provided.

For more information on improving the efficiency of your processes, contact our team of filtration experts.

Our Products

Leading the Industry with product solutions that fit your customers needs.

Parts Washing

Oil Recovery Treatment