In the summer of 2016, Pall reached two significant milestones: the first year anniversary since joining Danaher Corporation and the 70th anniversary of Pall. It began as a humble operation, one of thousands of new ventures spawned in the aftermath of World War II. It had but a single product for a single market. But that didn’t keep Dr. David B. Pall from dreaming — and laboring with a missionary zeal. Pall’s ascent to the top of its field is truly a casebook study in resourcefulness and resolve. It’s the story of how thousands of people over the years have applied their talents and skills to developing imaginative new products and finding new ways to serve the customer.

The company's history begins in 1941, when Dr. Pall made his first filter while working on the Manhattan Project. Dr. Pall had worked on a filter design to separate uranium 235 from uranium 238 and this filter was created by sintering powdered stainless steel. In 1946, Dr. David Pall founded a company called Micro Metallic Corporation in the most humble of beginnings. (The company's name would later be changed to Pall Corporation) What followed under Dr. Pall’s leadership and vision, was a story of growth from a tiny one-person shop behind a shoe-shine parlor in Brooklyn to the broadest-based filtration and separations company in the world in terms of technology and markets served. The common thread running through each decade, each year, is a palpable spirit of adventure that has enabled us to break meaningful new ground and capitalize on opportunities where we knew we could do something for the customer that no one had done before.

Today, Pall Corporation is a global leader in high-tech filtration, separation, and purification, serving the diverse needs of customers across the broad spectrum of life sciences and industries. Through it all, Pall has always been up to the challenge — and that quality makes us more confident than ever about the future of this company.

Time Periods

The Early Years

Economic recovery of war-torn Europe began, with a giant helping hand from the U.S. The energy and spirit that produced America’s incomparable fighting machine started to fuel a post-war economic boom. Shifting their emphasis from defense build-up, manufacturers started producing consumer goods en masse. Meanwhile, the housing industry blossomed, and countless new jobs and businesses were created. Among them was a tiny enterprise in New York with an unusual new material.

For two years, he labored in his spare time, nurturing a dream. The dream was to start his own business based on a product he had invented — porous stainless steel. For David B. Pall, a Ph.D. in physical chemistry, the vision seemed well within reach. His new engineered material would provide industry with a filter material vastly superior to anything previously developed. It would find a ready market, he was certain, in the field of chemicals where the trend toward higher operating temperatures, closer tolerances and more corrosive fluids had created the need for more durable filter materials.

The dream came to life in 1946 with the incorporation of Micro Metallic Company. The firm consisted of a single individual — Dr. Pall — working out of his cluttered garage. When this space became too cramped, he moved his bootstrap operation to more spacious quarters behind a shoe-shine parlor in Brooklyn. Disappointment soon set in, however. As sometimes happens with new engineering materials, users — in this case, filter manufacturers — shunned the product, and Dr. Pall realized he was attempting to grow a business on a hollow foundation. It would be some time before the dream would take flight.

The Rocky Road To Success

It might be called the best of times, the worst of times. Here are the recollections of some early shapers of Pall’s history.

Bram Appel

“I had $3,000 at the time, and that was the investment that started the company. Our first real facility was in the basement of a broken down building that had once been a candle factory in East New York. The furnace was tended by a man whose nickname was 'Tiny' and was as you might expect, about 6 foot 6 inches tall and weighed 300 pounds. The operation was primitive by any standard.

“The next few years were not easy. David (Dr. Pall) had originally planned to sell sheets of porous stainless steel to chemical manufacturers. This, of course, didn’t work, so we had to develop a facility to manufacture our own end products.

“Our low point financially came shortly after we purchased our headquarters in a burnt-out ice house in Glen Cove, New York. I arrived one month from Canada, where I lived, to find our bookkeeper, through an error, had issued checks that overdrew our account by $7,000. I went straight to the bank to meet payment on those checks, but being from Canada, there were problems. Eventually, a friend of my brother-in-law was coerced into loaning us the money, and we managed to keep the company afloat.

“I don’t want to leave the impression that all was a disaster. True, David was overworked to an extreme and there were pressures in all directions. But products were being developed and we were shaping our future by gradually establishing positions in a number of key industries, particularly aerospace.

“Before long, David persuaded his next door neighbor, a young accountant, to join him at Micro Metallic. The neighbor was Abraham Krasnoff. It was Abe’s breadth of vision, action and marketing expertise, coupled with David’s technical genius, that transformed a modest company into a global enterprise in 1989.”

Dr. David Pall

“My naivete and that of Mr. Appel make our original venture look like the height of folly. We did no market research prior to developing a product, there was no specific application in sight, we had no money for advertising, and no marketing or sales personnel. A great deal of what came to be known as ‘sweat equity’ (20- hour days were not uncommon), an eagerness to learn, a considerable contribution by lady luck, and some borrowed money, carried Pall through its birth period.”

Abraham Krasnoff

“Not long after we met in 1950, David Pall invited me to join his fledgling company which, at the time, had about 20 employees and less than $250,000 in sales. From the start, he was an excellent teacher, an inspiring leader and, with his boundless energy and enormous scientific skill and keen intellect, an innovator and problem-solver of the highest order. “We lived through good years and some frighteningly bad years, such as in the mid-60s when our principal business, the aircraft industry, went into a steep, steep decline. Even during this period, David never stopped innovating. He responded by becoming an expert in, and leading the company to, many different product areas. He was always working on some major advancement.”

Pall Answers An Urgent Call

In the summer of 1959, headlines in The New York Times related a frightening story: A Boeing 707 reported complete hydraulic failure and was forced to emergency land at New York International Airport (now known as John F. Kennedy International Airport). Hydraulic problems in another Boeing jet forced the pilot to jettison fuel over the Atlantic and use auxiliary systems to lower the landing gear.

An urgent call for help went out from the commercial airline industry. Pall responded promptly and decisively. Its engineers discovered that sophisticated new hydraulic systems on the 707s were sensitive to contamination. The problem could be traced in large part to the filters being used —impregnated paper filter elements of the type used in automobiles. These media were totally inadequate to protect valves, pumps and other critical components.

The solution from Pall was a new sintered wire cloth filter known as Rigimesh media. The Rigimesh filter was the first to offer an absolute filtration rating based on a glass bead test developed by Dr. Pall. The unique material not only provided the needed particle removal properties, but compacted a very large filter area into a small volume, which reduced filter size and weight. The Boeing 707 problem was soon resolved with the help of the Rigimesh material, prompting a Western Union telegram from a major airline congratulating Pall for “its outstanding action in avoiding the further grounding of 707 aircraft due to hydraulic system problems.” The accolades did not end there. For its work under pressure, Pall quickly gained credibility and a growing reputation in the field of aerospace fluid clarification. This led to a market leadership role in the 1950s, which it has never once relinquished.

Pall Begins to Grow

Leaving the awkward years behind, the company became focused on developing a line of porous stainless steel laboratory devices (filter funnels and aerators), as well as process filters for a growing range of industrial applications, including petroleum refining and film manufacturing. Through the latter half of the 1950s, it made giant strides as a custom metal filter producer for the aerospace industry and parts of the chemical process market.

Pall was no longer a fledgling operation. By the end of the 1950s, it had grown to a 400- member organization occupying 72,000 square feet of well-equipped plant space. It also boasted a talented team of 53 scientists and engineers who were working hard to build the credibility of this young and ambitious company. The growth was reflected in product sales, which escalated from $33,000 in the first full year of operation to $6.7 million for the fiscal year that ended July 31, 1960. In fact, Pall continued to turn a profit every year after that.

This early period also saw the growth of a business philosophy — a powerful strategic compass that could be counted on to point the company in safe and prudent directions. Briefly, it called on Pall to:

- Develop products requiring a high degree of technical skill to meet complex customer needs.

- Engage in activities within our realm of expertise.

- Build and maintain a superior technical and management organization.

- Seek expansion in technology-driven areas where continued change is likely.

That philosophy governs Pall to this day.

Pall's Initial Public Offering (IPO)

On November 21, 1957 Pall stock was publicly traded for the first time. Some 20,000 shares were offered at $5.00 per share. But, as it turns out, the big news had more to do with longterm potential than first-day results. Consider: if you had bought 100 shares of Pall Corporation stock that first day (total investment: $500), and reinvested the dividends only, your investment would be worth $1,164,208!* That translates into a torrid annual growth rate of 22 percent.

*Calculations assume: No brokerage commissions (paid from this source). No taxes paid on dividends (paid from other source). Dividends reinvested (fractions too).

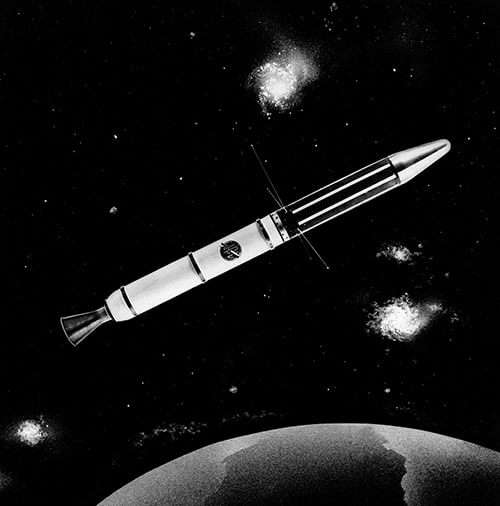

Pall's Contribution to the Space Program

"The first few attempts by the U.S. to launch a satellite on a Vanguard rocket (in the mid-1950s) were spectacular failures. The challenge of getting a satellite into space was finally given to (famed German rocket scientist) Wernher von Braun. I got a call one day from the head of Reliability for the Army, who reported directly to Dr. von Braun. He said they wanted to avoid any more failures, and asked if they could have a meeting with us. At that meeting, in addition to myself and the head of Reliability, were Dr. Pall and Bill Moog. Bill and his brother founded the company that made the servo actuators which controlled the direction of flight of the rocket. Pall filters were important parts of those actuators.

"At the meeting, the space people asked us what kind of filtration we would recommend, and we said the finest we could manufacture. Bill acknowledged this was a lot finer than he would normally recommend, but conceded that in this case, 'cleaner is better.' So, the U.S. went with Pall’s recommendation for the launch of the first U.S. satellite, Explorer 1, in January of 1958, with Pall protecting the hydraulic system of the Jupiter C rocket. To the relief of everyone, that launch and others that followed were hugely successful."

-John Farris (former Pall VP)

Time Periods

A New Focus

Counterculture became the emblem of a decade divided by war in Vietnam and racial confrontation. The greatest changes in American morals and manner since the 1920s characterized these years of unrest, mass marches and politicized campuses. Conflict also erupted in the Middle East and one African nation after another asserted its independence. For Pall, too, it was a period of tremendous change and soul-searching, culminating in a new business direction that put the company on a sound course for the future.

Changing Pall’s Direction

In 1964, Pall’s aerospace business — both military and commercial — fell from the radar screen, and the company began a difficult period of self-examination and renewal. It attempted, unsuccessfully, to add non-fluid clarification products to its aerospace and process lines through acquisitions.

During this time, an idea was conceived that would change forever the shape of Pall Corporation — disposable filters. The company concluded that the right direction was the development of proprietary disposable filters for distribution to large markets. Thereupon began a daunting series of tasks: developing unique filter media, putting them into useful forms, building production capacity and, just as complex, developing new marketing expertise and distribution systems. The wrenching period of readjustment began in the mid-60s and stretched to 1972. During that time, Pall kept a viable balance sheet and managed to maintain a low level of earnings while it underwent its transformation.

When the dust had settled, Pall was a much different company — not only in terms of product mix, but in terms of mission. It had adopted a narrow orientation and, within that window, was determined to become the leader in fluid clarification. The vehicle it chose was proprietary disposable filters designed and produced in standard forms suitable for broad distribution. The chemistry was soon working: sales grew to $26 million and Pall and its people were charged with a new sense of purpose.

Fueling An Engine Known As Innovation

From its earliest years, Pall has been powered by the spark of innovation. In the early 1960s, Pall became aware of the urgent need to more effectively remove water and oil from compressed air. Most manufacturers are dependent on compressed air for some parts of their operations. The problem is that compressed air, essentially a mixture of oil and water droplets, is also a source of contamination and even health hazards. Prior to the 1960s, the problem had been poorly addressed. Pall worked to fill the void. In 1966, its engineers developed the first high-efficiency filter for air and oil mist removal. This was followed by a series of products with ever higher removal efficiencies. And in 1986, Pall Profile filters— combining extremely high-efficiency with long service life — became the market leader.

“When Pall started in Europe, we knew we had to do things differently if we were to be successful. So, in every country we entered, we let the local nationals run their businesses, with support from Pall Corporation in America and the U.K. In no small way, we put these local leaders at the forefront of the customer relationship, and this was a fundamental difference in the way most Americanbased multi-nationals operated in the early 1960s. As it turned out, that strategy worked extremely well for Pall in Europe, and continues to work for us in other parts of the world.”

-Don Nicholls (former Pall Executive VP)

Pall Lands in Europe on the Wings of a Chemist

In these times of megabuck acquisitions and high-powered partnerships, Pall’s entry into the global arena in 1962 seems, in retrospect, almost too simple. Here’s how Dr. David Pall remembers it:

"We had a chemist working for us back in those days named Cyril Keedwell. He came to me one day and said his wife desperately wanted him to go to England with her while she visited her parents for a brief period. He told me he had a two-week vacation due him, but would also like to take a four-week leave of absence. “I thought about this for a long time and finally said,‘Cy, I want you to do a job for me while you’re there. I want you to find a company. It has to be small because we can’t afford a big one. I want a company that will give us a toehold in Europe.’”

Cy Keedwell performed flawlessly. He found a small engineering company in London named Lloyd and Hillman Ltd., whose principal product line was sensing devices and associated hardware for temperature and rate of flow measurements. A merger was consummated in March of 1962 — and Pall had an international presence. Lloyd and Hillman’s sales doubled in the first year of the merger. With the creation of Pall U.K. (Sales) Ltd. right after the merger, Pall began selling its complete line of filters and dryers in Europe through a growing distributor network. Pall’s European-based business flourished under the leadership of Maurice G. Hardy, and in 1966 Pall Europe Ltd. was formed to more aggressively develop the company’s enterprise across Europe.

Russia Turns The Tide For A Young Pall Germany

“Pall Germany began in 1965 with a small sales office, but it wasn’t until four years later that we got our first really big break. We were at a chemical industry exhibition in Frankfurt. A Russian delegation led by a prominent pharmaceutical professor was also there, and they listened carefully to the presentation we made on applying our filter technology to critical pharmaceutical applications. Before we knew it, the Russians had placed an order through an OEM for retrofitting every pharmaceutical plant in the country, from Minsk to Vladivostok, with Pall filters. The value of this order was over a million Deutsche marks and was more than all our other sales for the year combined. It was a great entry for us into the pharmaceutical filtration market as well as into Russia. It also enabled us to leave the cramped quarters we had been using and move into a larger building in a suburb south of Frankfurt.”

-Gerhard Weich (former group VP)

Distributors: One of Pall’s Core Assets

Since the earliest days, distributors have been important to the growth and success of Pall. With their inside knowledge of specific industries and geographic markets, they’ve been a valuable and highly dependable asset for Pall. As such, they’ve been warmly welcomed as members of the corporate family and given intense support. In return, they’re expected to be honest, loyal and enthusiastic sales representatives for Pall, working exclusively assigned territories and markets.

In the early 1960s, as Pall’s markets expanded, so did its distributor network, both in the U.S. and overseas. In Europe, distributors became the key to penetrating a huge and diverse marketplace in which Pall was anxious to build a presence. Recalls Derek Williams: “In order to effectively serve the European market, we looked for companies to become dedicated Pall distributors. We only considered people with integrity whom we thought would be with us for a long time. We realized then — and now — that the key to success is being surrounded by successful people.”

In the U.S., Pall’s earliest distributors were in the aerospace market. When Pall entered the Industrial Hydraulics (IH) marketplace in the mid-60s, it began dealing with distributors who not only sold but stocked its products. Today, Pall products are sold through distributors who specialize in specific markets, such as hospitals, aerospace and nuclear power plants, as well as through its own sales force. The vehicle for a given region depends on the easiest and quickest route to market — and the one that makes most sense for the customer. In the U.S., Pall products are sold mostly through a seasoned team of distributors, while in countries like the U.K., France and Japan, direct sales forces are the primary sales mode.

Why use distributors instead of just increasing its own sales capability? The distributors have knowledge of their local markets, and a closeness to their customers that is very hard to duplicate. Moreover, most Pall distributors are intensely motivated and entrepreneurial. They have a lot at stake…and a lot to gain if they’re successful. So does Pall, and it has steadfastly recognized and rewarded its distributors over the years with the strongest support in the business. Pall distributors know that if they remain dedicated and productive, they too will grow — and prosper.

Pall's Walk On The Moon

Astronaut Neil Armstrong’s epic walk on the moon proved to be “one small step for man” — and another remarkable success for Pall Corporation. That’s because a porous metal heat exchanger developed by Pall served as a virtual lifeline for Armstrong throughout his mission. Residing in the backpack of his spacesuit, the device served as a mobile air conditioning unit, lowering the temperature inside his spacesuit.

That was not the end of Pall’s rendezvous with history on July 20, 1969. Our bacterial filters were part of the Lunar Module, which carried Armstrong and fellow astronaut Edwin Aldrin from the mother ship to a soft landing on the moon’s surface. In this case, Pall filters played a protective role, screening the gases that were vented from the Lunar Module as part of the process to equalize cabin pressure with the near-vacuum conditions that existed on the moon.

Pall’s success with the manned space program continues to this day. Our products reside in multiple components of space shuttles, as well as the International Space Station, which was launched in 1998.

Time Periods

Gaining Confidence and Sales

The slumbering Asian giant came to life as China began to normalize its relations with the West and Japan emerged as a world economic power. In the United States, the spectacle of Watergate and a President who purported to be above the law at once riveted and shook the American public. The economy also took its blows: an Arab oil embargo sent prices soaring and a combination of inflation and recession gave rise to the condition known as “stagflation.” Despite these often turbulent times, Pall continued to grow, and by the end of the decade had claimed its rightful place on the Fortune 1000.

Becoming the Technical Leader in Fine and Ultrafine Filtration

In the 1970s, new horizons were opening up to Pall. Pall filters were now meeting a new generation of applications and needs in fields as diverse as purification of pharmaceuticals and protection of sensitive hydraulic components. As a result of its growing expertise and product capabilities, Pall became the acknowledged technological leader in fine and ultrafine disposable filtration.

This new thrust helped to reenergize Pall’s aerospace filter business, which had experienced difficult times in the mid-60s. Pall had long been the leading supplier of fine hydraulic oil filters for aircraft through metal filters. With the advent of disposable filters, a robust new worldwide market opened up in both the commercial and military sectors. This market was enhanced by the conversion of many hydraulic systems to disposable filter use. By 1973, about 60 percent of Pall’s aircraft business was fine filtration disposable filters, and aerospace sales began to show significant growth for the first time in nearly ten years. Not just aerospace, but the success of the entire company was now inextricably linked to the development, manufacture and sale of disposable filters.

A New Filter Is Born

It was over lunch with his stockbroker that Dr. Russell Patterson, neurosurgeon at New York Hospital, offhandedly discussed a problem he was noticing. Patients put on heartlung machines during neurosurgery were developing postoperative neurological problems. The source of the problem, according to Dr. Patterson, was tiny air bubbles in the circulating blood. It was the same culprit that oftenran amok during openheart surgery.

After listening intently, the stockbroker had a suggestion: why not call Pall Corporation, the experts in filtration technology? Dr. Patterson took his advice and called, totally unaware that his conversation would help launch a new class of filter products with the remarkable ability to reduce postoperative complications. In a short period of time, these products would become staples in hospitals around the world.

The Health Care Industry Becomes a Major Growth Story

As the new decade unfolded, Pall set its sights on a new target – the hospital market. For the first time Pall marketed disposable filters to purify liquids or gases being administered to hospital patients or, in the case of open-heart surgery, to remove harmful particles from the patient’s own blood.

Pall created a new sales company in 1971 to focus on the new opportunity. It introduced the Ultipor blood filter for the removal of microemboli (small particles) from transfused blood, and extracorporeal blood filters to protect patients during open-heart surgery from gas bubbles as well as solid microemboli in the circulating blood. These products won quick acceptance and usage among prominent surgeons. Pall gained even greater visibility within the hospital market following its introduction in 1976 of an intravenous filter. This product automatically eliminated air from intravenous fluids while protecting the patient from bacteria and other contaminants. These innovations soon translated into significant sales growth. Pall’s hospital sales rose from $400,000 in 1971 to $1.5 million in 1973 to $10 million in 1978. On the heels of this success, Pall began distributing its products in Europe, Japan, and South America.

Kudos for an Inventor Extraordinaire

On July 31, 1976, Pall Corporation celebrated its 30th birthday. It was a fitting occasion to honor an individual whose tireless work over more than three decades had built a global enterprise of 1500 employees and sales of $56 million. And honor Dr. Pall they did, with numerous awards and citations from government officials, technical societies, customers and colleges. Perhaps the most memorable gift, however, was a beautifully bound book —presented to him by the employees of Pall — containing copies of Dr. Pall’s 72 U.S. patents. Coupled with the additional 71 U.S. patents that had been issued to other Pall inventors during the first 30 years, it was clear why the company now occupied a leadership role in its field.

Global Growth Outpaces Domestic

Pall was becoming a global enterprise faster than most people realized. For the fiscal year that ended July 1978, sales overseas comprised about 40 percent of the total volume of $88 million. The company was now growing faster internationally than domestically.

The Pall Difference: Scientific and Laboratory Services

For over 55 years, it has stood as one of Pall’s most powerful tools, a worldwide bridge with customers capable of solving complex contamination problems. That tool is Pall’s Scientific and Laboratory Services (SLS). Created in 1962 as the Contamination Service Group, its name and mandate were significantly changed in 1976 to reflect the growing importance of this organization to the success of the company. In addition to providing first-rate customer support, SLS technical experts were called on to support and uncover novel new applications and markets for Pall technologies through the development of “technical marketing positions.”

SLS flourished under the new charter and leadership of Erwin Kirnbauer, former SVP. The group evaluated the performance of new products under development by Pall’s R&D units and investigated new markets for which only limited information was available. Above all, though, “SLS has continued to work hand in hand with customers, providing technical, scientific and laboratory assistance needed to solve complex filter application and contamination control problems. SLS activities are often initiated in response to a customer request, or through the Pall Scientific Liaison Program which was created to provide proactive technical support to customers with advanced filtration questions and requirements,” said Erwin Kirnbauer.

SLS adds further value to the customer relationship through its global reach. Support is provided through a network of 400 scientists and engineers (many with Ph.D. degrees) deployed at some 20-plus well-equipped laboratories throughout the Americas, Europe, Australia, and Asia. These labs, unsurpassed in the industry, allow for such sophisticated activities as particle counting, contamination analysis, gas and liquid chromatography, light and electron microscopy, hematology and biochemical diagnostic testing, among many others. Whether the problem is in Korea or Germany, Brazil or the United States, SLS has proven its ability time and again to deliver a timely and intelligent solution for customers.

Time Periods

Exploring New Horizons

A revolution was born as small, powerful computers invaded the home and workplace, ushering in the much heralded Information Age. Fractures began to appear in the Communist world, triggering epochal change that ended in the 1991 collapse of the Soviet Union and the cessation of the Cold War. Wall Street provided a fitting epitaph for the decade as fortunes were made while markets toppled. Pall’s ongoing search for new opportunities earned it a growing presence in the Pacific Basin, Europe and South America, as well as an emerging role in improving the quality and safety of the world’s blood supply.

Pall played a Major Role in Three Mile Island Cleanup

Three Mile Island. The name continues to evoke haunting memories of a nation’s most serious nuclear accident. And though the infamous event on March 28, 1979 at the nuclear power station in the Susquehanna River near Harrisburg, Pennsylvania, was miniscule in its health consequences, it has had a profound and lasting impact on the nuclear power industry.

The cleanup of the damaged radioactive Unit 2 reactor required nearly a decade of intense work at a cost of over $1 billion. Pall was an integral part of that project. The company was approached by General Public Utilities, the owner of the nuclear reactor, to provide a system to be used in the cleanup of radioactive water, which had gathered to a depth of 20 to 30 feet above the damaged core of Unit 2. By recirculating that water through Pall filters, visual clarity would be maintained so that workers could remove debris and rubble with remote tools.

On April 29, 1983, a meeting was held at Pall’s Scientific and Laboratory Services Group in Glen Cove, New York to map out a strategy. The intense research and development program that followed resulted in the development of an entirely new product: a sintered stainless steel filter which offered significant advantages over other solutions that had been proposed. Among the benefits were a simple, continuous mode of operation and elimination of a complex filter control system.

The new filter was later named Pall Porous Metal Membrane (PMM) filter and extensive tests by the engineers at the cleanup site underscored its effectiveness. Working under tight time constraints, Pall’s plant in Cortland, New York began producing the material and in less than a year had manufactured and delivered 50 canisters filled with PMM media for the cleanup of damaged Unit 2.

Ultimately, two million gallons of cleanup water were passed through the PMM modules and 20,000 lbs. of irradiated solids were removed. For its efforts, Pall was presented with a plaque from General Public Utilities for its “significant contribution” to the success of the Three Mile Island cleanup. The story does not end with Three Mile Island, however. The new filter technology that emerged from the project has since found its way into a number of important — albeit more routine — applications at nuclear power stations.

Pall Goes Underground and Underwater

Pall’s technical expertise has figured in some of the most celebrated engineering projects of our times. Construction of the $10 billion Eurotunnel under the English Channel between England and France, begun in the mid-80s, is a case-in-point. With installation subject to financial penalties of up to $938,000 per day in the event of project overruns, reliable operation was absolutely essential to the project.

Perhaps the single most critical operational requirement was the dependability of the massive machines which bored and erected the concrete structure of the tunnel. Keeping these machines at peak operating efficiency depended heavily on the performance of their hydraulic systems. Aware of Pall’s experience in the field, the manufacturer of the hydraulic systems used in the boring machines called on Pall’s Scientific and Laboratory Services (SLS) facility in Portsmouth, England for help.

SLS agreed to take an active and immediate role, beginning with the specification of filtration and cleanliness levels at both the design and build stages in order to ensure troublefree operation. SLS also monitored the project’s progress, provided instruction to the maintenance staff, and set-up a quality system to measure and ensure performance. Thanks in part to Pall’s help, the formidable task of tunneling under the English Channel was completed six months ahead of schedule.

Protecting Patients from Foreign Invaders

Pall’s family of health care products continued to evolve with the changing needs of physicians and patients. In the area of hematology, the health care profession had been aware for many years that patients given blood transfusions frequently developed fevers and allergic reactions, and that repeated transfusions resulted, in the body’s rejection of further transfusions.

By the late 1970s, immunologic research had identified leukocytes, or white blood cells in donor blood, as the major source of the problem. Leukocyte reduction by filtration came to light as a possible solution. But filtration was not able to achieve the level of leukocyte reduction that the medical community felt was necessary to maximize patient safety and ensure the effectiveness of the treatment.

A research team under the direction of Dr. David Pall took up the challenge in 1985. What emerged from their laboratories after two years of intense work was a series of new filters that surpassed anything on the market. They made it possible to turn any red cell or platelet component into a significantly leukocyte reduced blood product for safer effective transfusions. In 1988, Pall Corporation began selling its new leukocyte reduction product line, which could be attached to any blood transfusion bag at the patient’s bedside. The health care community was clearly excited, and filter sales soared. By the end of the year, more than 650 hospitals were using Pall leukocyte reduction filters, and they continue to be the most widely used hospital filters worldwide.

Blood collection centers also became major users of Pall filters. For this application, Pall scientists developed another family of leukocyte reduction products for the filtration of blood at the time of donation, as well as during the storage life of the blood. The sale of Pall blood filters to blood centers rose dramatically in the 1990s as a greater awareness of the benefits of leukocyte reduction began to take hold worldwide. Pall filters continue to play a pivotal role in improving patient outcomes, shortening hospital stays, and cutting health care costs.

Time Periods

Reaping The Rewards

The 1990s stirred up a brew of terrorism, civil war and epidemics. But in other ways, the world had never looked better — or smaller. The Global Village was at last, reality. It’s a world in which products, markets, technologies, even business strategies, had converged. Indeed, the real frontiers are no longer territorial; they are markets and ideas. Pall, after 50 years of hard work and preparation, found itself perfectly positioned to enjoy the exciting opportunities unfolding.

Frequently in Pall’s history there have been compelling — and gratifying — examples of the power of its products. None is greater, however, than Centrisep air cleaners installed in U.S. Army and Royal Air Force (U.K.) helicopters undergoing combat in Operation Desert Storm. Centrisep air cleaners were major contributors to keeping the helicopters in the air and pilots alive during the war against Iraq in early 1991.

The problem that Army aviators faced at the outset of the war was frightening: rapid power loss as their engines loaded up with sand and dust from the harsh desert surface. As one helicopter pilot later explained, “Operating a Cobra meant playing Russian Roulette as to whether you could get in and out of Iraq without engine loss.” Pall’s solution was the Improved Particle Separator (IPS), part of the Centrisep family of air cleaners. With lives at stake, it was essential that this product be brought to life as quickly and efficiently as possible.

It was accomplished, as Pall marshalled its own forces for an extraordinary, round-the-clock effort in both the U.S. and U.K. The Improved Particle Separator was designed, manufactured, qualification tested, put through full flight trials, and approved by the U.S. Army in a total of 42 days. In all, 515 units were manufactured and shipped from November 1990 through February 1991.

The results were dramatic and swift. Availability of the U.S. Army’s UH-1 Huey helicopters, less than 50 percent at the beginning of Desert Storm, rose to nearly 90 percent after the Improved Particle Separators were installed. Impressive results also occurred with Apaches, Cobras, Blackhawks, CH-47 Chinooks and other helicopters outfitted with the new filter systems. For their part, the British forces experienced virtually no engine losses during the entire Desert Storm campaign thanks to the Centrisep Particle Separators. A young U.S. warrant officer who flew numerous missions during Desert Storm perhaps summed it up best. Stopping by Pall’s booth at a U.S. Army Desert Storm Exhibition in St. Louis, Missouri after the war, he thanked the engineers and designers on hand for their exceptional efforts. In all probability, he said, the Centrisep air cleaner had saved his life.

Pall's Quality Leadership and Innovation

The success of Pall Corporation during its first five decades is synonymous with the history of its quality leadership. During the 1950s, Dr. Pall was proactively building quality into each of the company’s filter products. Not content with just inventing technologically advanced filtration media, Dr. Pall also focused on designing robust filter configurations and the equipment to manufacture them. To help ascertain acceptable quality levels, he invented and patented the first non-destructive filter integrity test.

What Dr. Pall did for product quality, Abe Krasnoff did for service quality. As Chief Executive Officer for 20 years and the company’s second Chairman of the Board, Abe made certain that everyone in the organization “always did what was right for the customer.”

Pall’s third Chairman and CEO, Maurice Hardy, took quality to another level. He led over 6,000 employees through continuous quality improvement training. He was also one of the first in the industry to see the importance of the ISO 9000 series of quality system standards. Beginning in 1987 with Pall facilities in Great Britain, he worked to bring the entire corporate universe of 40 facilities, including manufacturing plants, distribution centers and sales centers, up to ISO 9001 or 9002 standards.

Eric Krasnoff, Pall’s fourth Chairman and CEO, made strategic quality planning the linchpin of the company’s worldwide effort to achieve customer satisfaction. Continuous improvement became the operating standard for all Pall activities, and Process Mapping was a critical tool by which to reach that goal. By understanding how a process works, Process Mapping makes it possible to eliminate bureaucracy and waste, reduce cycle times and, ultimately, provide increased value to our customers. Underlying the quality initiative is the empowerment of each Pall employee to take personal responsibility for quality improvement and, in the process, reach their full potential.

Pall’s leaders have indeed served as pioneers. At a time when very few companies in the industry were competing on the basis of quality, the company established itself as the quality innovator. This commitment has led to steadily increasing productivity, customer satisfaction and profitability. By refusing to accept the status quo, Pall had created a quality “mindset” that would continue to drive the company’s performance for years to come.

High-End Separations Provides a Pathway Into the 21st Century

With its traditional fluid clarification business firmly established, Pall began posing in the early 1990s a provocative question: where would future sales and earnings growth come from? The answer was soon forthcoming. Pall Corporation, under the leadership team of Eric Krasnoff and Jeremy Hayward-Surry, would add the complementary field of high-end separations to its portfolio. And with that one bold stroke, the company increased the market potential for its products and technologies worldwide.

While the fluid clarification business is made up of thousands of small orders, much of it replacement of disposable filters, the separations business represented a totally different set of dynamics — and opportunities. Complete separations systems, which remove large amounts of sludgy contaminants that are otherwise difficult to filter, can easily command prices of $250,000 to $2 million. Moreover, a sale can take as long as a year to 18 months to conclude. Just as important, high-end separations gave Pall access to an exciting range of applications across its Fluid Processing, Aeropower and Health Care businesses that were previously out of reach.

Almost as soon as it was unveiled, separations proved to be an unqualified success. It was strengthened through Pall’s acquisition of Filtron, whose microfiltration and ultrafiltration membranes met the separation needs of customers in the laboratory and life sciences markets. By fiscal 1995 the expansion of Pall’s business had helped the new leadership team achieve its avowed goal: restore double-digit, top-line growth. What’s more, Pall now had a strategy for growing the business in a logical, cost-effective way that promised to carry it well into the 21st Century.

Pall Takes Up Residence on the Internet

On May 26, 1996, Pall Corporation took another giant step into the future. Our website on the Internet was unveiled, and it was clear that marketing would never be the same. By tapping into the Internet, Pall became part of a frenzy that some compared to the Gold Rush era of the 1850s. Everyone wanted to be on the Internet. For businesses, it was an unprecedented opportunity to reach a worldwide audience, swiftly and cost-effectively. For customers, it meant easy access to the information they needed to do their jobs better. With statistics showing that 30 million people currently have access to the Internet, and over 550 million are expected to have it by the year 2000, was there any other place to be?

Obviously not, Pall realized, and set to work designing a web site. This was no simple task given the tremendous competition for the customer’s time. A way must be found to not only draw customers in, but keep them there with useful information. The ultimate goal: build a web site that is the definitive source for filtration and separations information. As the early success of the site has since shown, Pall is well on its way. The site invites viewers to enter via a range of industries — microelectronics, health care, energy, industrial manufacturing, chemicals & plastics and aerospace/defense. Once there, they can navigate through a veritable sea of information — information that not only informs, but challenges customers to find a solution to their problems by partnering with Pall. Pall’s presence on the web is rapidly evolving, with the possibilities seemingly endless. New product roll-outs to worldwide audiences and electronic availability of product catalogs with full-color graphics loom on the horizon. And with real-time video on the Internet not far away, another exciting marketing dimension could soon be opening up for Pall. For now, though, the first bold step has been taken. And Pall has at its fingertips an electronic platform to carry it well into the next century.

Dr. Pall Caps a Brilliant Career with the National Medal of Technology

In the capstone to an illustrious career that has yielded 108 U.S. patents and the respect and admiration of his profession worldwide, Dr. David B. Pall was awarded the National Medal of Technology on November 13, 1990 by President George H.W. Bush in ceremonies at the White House. The National Medal of Technology is the highest award bestowed on American technologists by the President. It recognizes extraordinary individuals for their outstanding contributions to improving the well-being of the United States through the development and application of technology.

Dr. Pall had indeed met that criterion. In a career spanning four decades, he fathered technologies that spawned hundreds of successful products resulting in improved safety, efficiency and economy across a broad sweep of industrial and health disciplines. He used a rare combination of creative genius and business savvy to transform a one-man shop behind a shoeshine parlor into an acknowledged world leader in the field of fine filters and fluid clarification devices. For the soft-spoken, scholarly individual who read a book a day as a child, the National Medal of Technology was a fitting and, perhaps expected tribute. He had risen to the top of his business field — but had remained a scientist throughout. He had built a company that reflected his values and intelligence.

Bram Appel summed it up best at a dinner long ago honoring his life-long friend: “Pall Corporation is stamped with the ethos of David Pall. Because he is brilliant, David surrounded himself with brilliant people. Because he is modest, he surrounded himself with people who eschew arrogance. And because he is creative, he assembled an imaginative and highly inventive team that is the pure essence of Pall.”

Time Periods

Realizing Life's Potential

Dr. David B. Pall died on September 21, 2004, at his home in Roslyn Estates, N.Y. after a long illness. He was 90 years old. Armed only with an idea -- a revolutionary filtration material, Dr. Pall founded Pall Corporation in a Queens, N.Y. garage. Over the next half century, Dr. Pall's genius roamed far and wide to solve critical problems across a broad range of health care, environmental and industrial applications. A remarkable number of his inventions have become indispensable products used every day for filtration applications such as blood banking, drug production, and aerospace systems. He was the named inventor on 181 U.S. patents.

Shortly after his death, a study conducted at a leading prion research institute in Europe, found that the Pall Leukotrap® Affinity Prion Reduction Filter reduces infectious vCJD prions from red blood cell concentrates below the limit of detection of the Western blot assay. The investigators concluded that these results suggest that the new filter can be used to remove different strains of infectious prions, including vCJD (the prions that cause mad cow disease)

In 2008, Dr. Pall was posthumously inducted into the National Inventors Hall of Fame. Dr. Pall was selected for the Hall of Fame distinction in recognition of his leukocyte reduction filter (U.S. Patent No. 4,925,572), which he developed in response to the aplastic anemia that took the life of his first wife. The leukoreduction filter prevents rejection of transfused blood and eliminates the transmission of blood borne disease via transfusion, by removing white blood cells from donor supplies. Introduced in the early 1990’s, Pall’s leukoreduction filter has become the standard of care for transfusion recipients by improving patient outcomes and reducing health care costs. It is a bellwether of the company’s leadership in medical and biopharmaceutical filtration technologies.

In 2009, two Pall mobile water treatment systems supplied to the Australian Army as part of "Operation Padang Assist", the Australian government’s humanitarian response to catastrophic earthquakes in Indonesia. Two water points established by the Australian Department of Defense on the beach of Padang used the Pall designed and manufactured systems to convert sea water into potable water for up to 75,000 households.

On August 31, 2015, Danaher completed the merger of Pentagon Merger Sub, Inc., a New York corporation and an indirect wholly owned subsidiary of Danaher, into Pall and, as a result, Pall had become an indirect wholly owned subsidiary of Danaher Corporation.