Discover the best filtration solutions for various stages in lithium battery manufacturing. Contact our experts.

Importance of filtration for lithium battery manufacturing

Filtration is crucial in lithium battery manufacturing, improving performance, safety, and longevity. Our solutions are designed to reduce impurities, improve process efficiency, and support the production of battery-grade materials essential for next-generation energy storage systems.

Our advanced technical expertise acquired from working with customers in markets, including mining, microelectronics, specialty chemicals, polymers, and automotive, has already been applied to customers across lithium battery manufacturing. Combining global reach with local knowledge, we can offer exceptional support and efficient filtration and separation solutions to help you reach your quality and efficiency goals.

Challenges in Lithium Battery Manufacturing

Manufacturers face increasing pressure to reduce carbon emissions and improve the purity of materials used in lithium-ion battery production. Pall’s filtration systems address these challenges by offering best-in-class filtration solutions, helping to ensure consistent quality and reduce defect rates across the battery supply chain.

From mining and mineral processing to final assembly, we can help you achieve greater productivity in the lithium-ion battery market by:

- Improving end-product quality

- Enhancing throughput.

- Optimizing process to reduce total cost of ownership.

- Reducing costly downtime and maintenance operations in your production processes

- Sustainable manufacturing helps you to reduce your carbon footprint.

Multi-stage filtration process for battery manufacturing

-

Base Materials

-

Battery Active Material

-

Battery Cells

-

Recycling

Lithium Processing from Brine

Brine sources include underground lakes or Salars, hot geothermal reservoirs and brines associated with petroleum production. Improved filtration and separation can play an important role in improving both the process reliability for producing consistent high purity products and also for improving the product yields, reducing product re-work, reducing operation costs and reducing carbon intensity in production.

Lithium Processing from Spodumene

Spodumene concentrate ore is converted into either Lithium Carbonate or Lithium Hydroxide for use as an essential component to make Lithium-Ion Batteries. Improved filtration and separation can play an important role in improving both the process reliability for producing consistent high purity products and also for improving the product yields, reducing product re-work, reducing operation costs and reducing carbon intensity in production.

Cathode Active Materials

The cathode or positive electrode is made of a very pure mix of metal oxides containing lithium. The more uniform its chemical composition and crystal structure, the better battery performance and life is. To meet the EV battery manufacturers’ specifications, high performance filtration solutions are required at the different fabrication stages to produce pure and uniform cathode active materials.

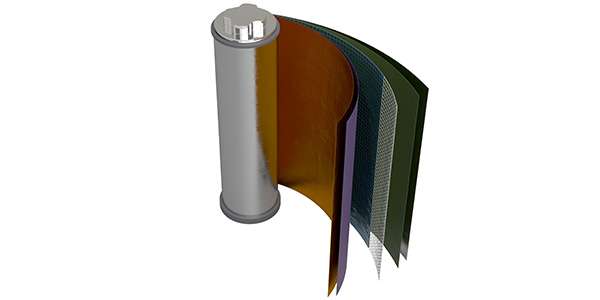

Separator

For the separators to function optimally, it is important that the polymeric materials they are made of are filtered prior to their formation. These high-performance filtration solutions are used widely across many different fabrication processes to achieve the separators required technical specifications, cleanliness quality, and uniformity of the polymeric materials.

Electrolyte

To maximize the performance of the electrolyte, i.e. high ionic conductivity associated to a high chemical/electrochemical stability, solid particle content must be minimized. To do so, the liquid electrolyte must be filtered before the filling phase. Moisture in the electrolyte can result in the formation of hydrofluoric acid (HF) from fluoride lithium salts. Since HF can corrode certain metals, such as piping on equipment or internal battery components, it is critical to prevent moisture from coming in contact with the electrolyte

One of the key considerations in the EV market is the quality and cost of batteries. Compared to small devices, batteries for electric cars need to meet much higher standards for performance and safety. This is where Pall’s filtration products come into play. They play a crucial role in improving the manufacturing process of lithium-ion batteries, ultimately helping to reduce operating costs.

Pall Filtration Solutions for Lithium-Ion Battery

Looking to enhance your lithium battery manufacturing process? Contact our team to learn more about the best filtration solutions for lithium battery separators and how Pall can help you meet your performance and sustainability targets.

Frequently Asked Questions

What are the best filtration methods for lithium battery separators?

The best filtration methods for lithium battery separators involve polymer melt filtration and purification of additives and coatings used in the separator film production process. Pall’s advanced filtration solutions ensure that the polymeric materials used to manufacture separators meet strict technical specifications for cleanliness, uniformity, and performance. These methods help prevent short circuits and ensure safe operation of lithium-ion batteries by removing contaminants before and during separator formation.

How does Pall support lithium battery manufacturing?

Pall supports lithium battery manufacturing by providing specialized filtration and purification technologies across every stage of the process—from raw material preparation to final cell assembly. These solutions enhance battery quality, improve throughput, reduce downtime and helps to support sustainable manufacturing practices. Please contact us on the form provided on this page to speak to our experts.