Entre em contato com um especialista em cervejeiras abaixo.

Sistemas comerciais de filtração de cerveja

Descubra todo o potencial do seu processo de fermentação de cerveja com nossos inovadores sistemas de filtração de cerveja

O papel da filtração na cervejaria moderna

A filtração da cerveja é essencial para atender aos altos padrões necessários para preservar o sabor, a pureza e o frescor exclusivos da cerveja. Fornecemos sistemas avançados de filtração de cerveja comercial personalizados para cervejarias de todos os tamanhos, desde operações artesanais até produtores globais. Descubra como as cervejarias filtram a cerveja usando nossas tecnologias comprovadas que melhoram a clareza, o sabor e o prazo de validade.

Filtragem de cerveja para qualidade, consistência e estabilidade da prateleira

A qualidade da cerveja é essencial. Nossos avançados sistemas de filtração de cerveja comercial ajudam as cervejarias — de artesanais a globais — a obterem clareza, estabilidade microbiológica e ótimo sabor. Ao filtrar a cerveja de forma eficiente, você pode estender o prazo de validade, reduzir o desperdício e otimizar seu processo de fermentação e produção de cerveja.

Nossas soluções ajudam as cervejarias a filtrarem a cerveja, reduzindo custos e apoiando a sustentabilidade. Com melhor eficiência da água, contaminação reduzida e menor manutenção, você obtém qualidade consistente e operações simplificadas.

Vamos falar sobre como a Pall pode ajudá-lo a melhorar a qualidade da sua cerveja, reduzir o desperdício e simplificar suas operações. Descubra nossas soluções eficazes para cada etapa do processo de fermentação de cerveja abaixo.

Saiba mais sobre nossos sistemas IoT de cerveja

Descubra nossas soluções de filtração para cervejeiras abaixo:

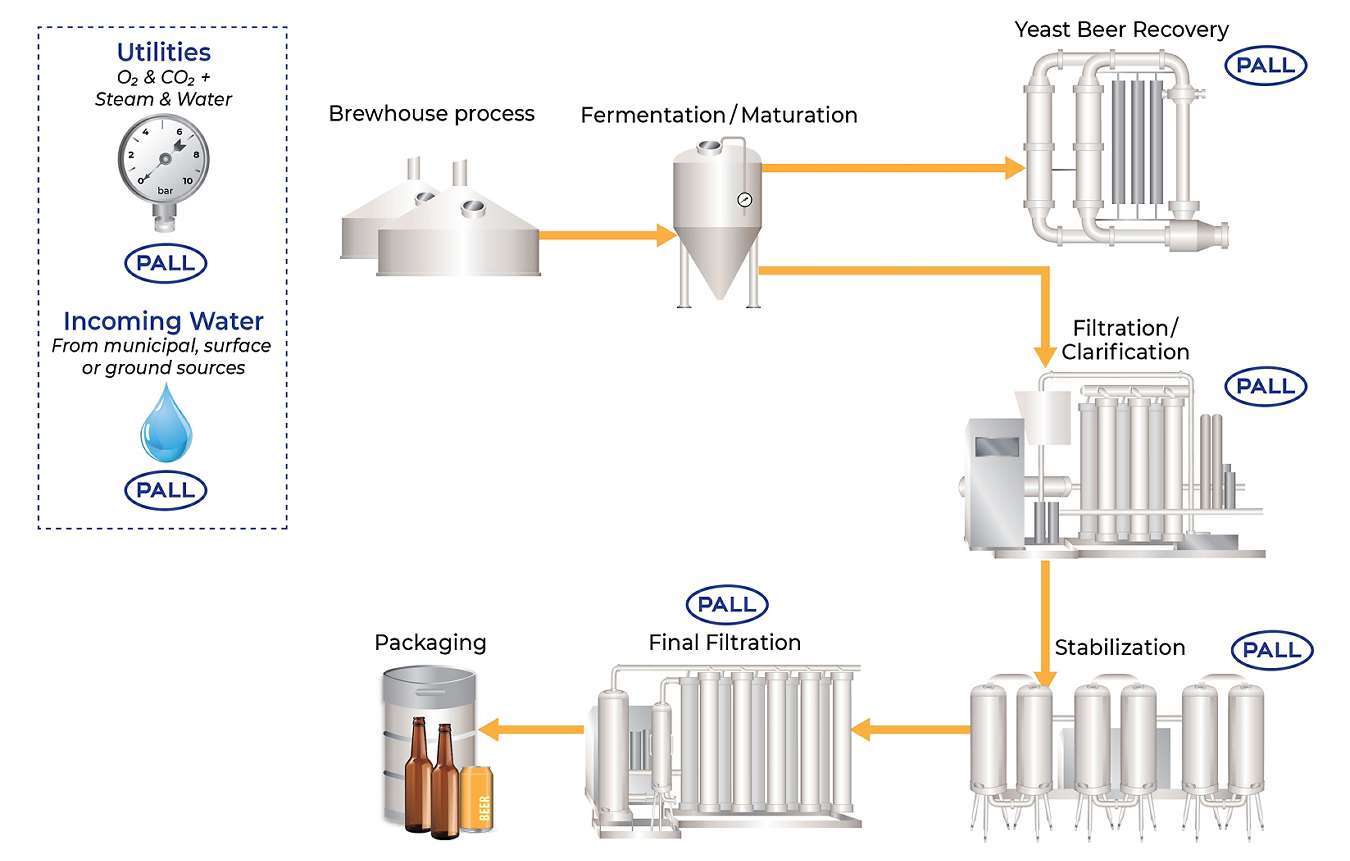

Etapas do processo de filtração de cerveja:

A Pall Food & Beverage é a fornecedora de soluções para o processo pós-fermentação, como mostra o diagrama a seguir.

Perguntas frequentes

Como as cervejarias filtram a cerveja?

As cervejarias filtram a cerveja por meio de um processo de várias etapas que inclui clarificação, estabilização microbiana e filtração final. Essas etapas removem turbidez, levedura e bactérias para garantir clareza, sabor e estabilidade na prateleira.

O que são sistemas comerciais de filtração de cerveja?

Os sistemas comerciais de filtração de cerveja são tecnologias de nível industrial usadas pelas cervejarias para filtrar a cerveja em escala. Eles removem partículas indesejadas, preservando o sabor e garantindo a segurança.

Por que filtrar cerveja é importante?

A filtração da cerveja melhora a clareza, aumenta o prazo de validade e garante uma experiência de sabor consistente. Ela é essencial para atender às expectativas do consumidor e aos padrões regulatórios.