Mantenha-se atualizado com as mais recentes soluções de filtragem para mercados de geração de energia

Seu parceiro integrado de filtragem e separação em geração de energia

Desde 1946, a Pall é líder em tecnologias de purificação de fluidos para a indústria de geração de energia. Nossas tecnologias avançadas de separação e fabricação de alta qualidade fornecem soluções de filtragem para todos os fluidos de usinas de energia, garantindo energia mais limpa, segura e confiável com maior lucratividade. Oferecemos carcaças de filtro , elementos de reposição, sistemas de monitoramento e chave na mão para qualquer tamanho de aplicação, desde pequenos fluxos e instalações simples até grandes fluxos e sistemas complexos.

Explore produtos, sistemas e soluções de geração de energia com baixo teor de carbono

Explore nossas soluções em geração de energia tradicional

Serviços de aluguel de filtros

Uma frota de equipamentos móveis disponível localmente para aluguel de curto e longo prazos para proteger ativos de processos críticos, proteger a produção e melhorar a qualidade do produto.

Produtos em destaque para várias aplicações de filtração

-

Filtração hidráulica e de lubrificante

-

Purificadores de óleo

-

Remoção de verniz em sistemas de óleo

-

Monitoramento das condições do fluido

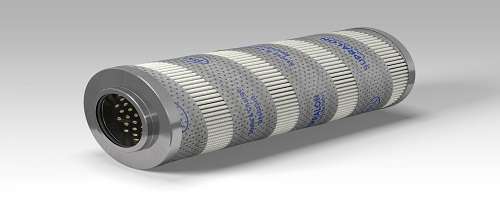

Filtros Athalon™

O máximo em desempenho de filtro de óleo hidráulico e lubrificante

Nossas carcaças de linha de retorno e pressão Athalon™ fáceis de instalar contêm elementos filtrantes feitos de fibras inorgânicas inertes em uma configuração de projeto Laid-Over Pleat (LOP) sem núcleo que maximiza a capacidade disponível do filtro para prolongar a vida útil do filtro. O elemento filtrante é resistente a alta tensão de fluxo cíclico e carga de sujeira, tem uma classificação de eficiência Betax(c) ≥ 2000 (a classificação mais alta do setor atualmente) e possui propriedades antiestáticas para evitar efeitos prejudiciais da descarga eletrostática. As carcaças do filtro Athalon também são rápidas, seguras e fáceis de manter, desparafusando a tampa do filtro em vez de remover o corpo do filtro por completo.

Elementos de filtro de substituição Supralon

A substituição direta dos elementos de filtro Pall Coralon e Ultipor III existentes e algumas marcas alternativas de carcaça de filtro

A contaminação da água promove a corrosão e o desgaste dos componentes do sistema de fluidos, resultando na redução da vida útil dos componentes e aumento dos custos de manutenção. Ele também degrada as propriedades do fluido, levando a uma lubricidade e capacidade de carga reduzidas capacidade, oxidação do óleo e a formação resultante de ácidos e precipitação aditiva. As consequências são a redução da vida útil do fluido e aumento dos custos de aquisição e descarte do fluido

As soluções de purificação de óleo da Pall removem 100% da água livre 80% da água dissolvida, também removem 100% dos gases livres e arrastados e até 80% dos gases dissolvidos.

Selecione o purificador de óleo Pall para:

- Remoção de água, gás e partículas de alto desempenho

- Extensão da vida útil do fluido

- Corrosão minimizada dentro dos sistemas

- Descarte de fluido reduzido

- Custos operacionais reduzidos

- Maior confiabilidade do equipamento

- Operação automatizada simples

- Opção de monitoramento remoto

Assista à demonstração da tecnologia de desidratação associada ao HNP

O verniz é o depósito de filme fino e insolúvel que se forma em superfícies molhadas de óleo dentro de um sistema de lubrificação de turbina, incluindo rolamentos e servoválvulas. Sua formação é frequentemente atribuída a temperaturas operacionais mais altas, reservatórios de fluido menores, alto serviço cíclico e estoques de base de fluido que têm menor solvência para verniz precursores.

Você não pode vê-lo, mas sabe que está lá, derrubando seu sistema hidráulico em um componente de uma vez.

Quando o verniz se forma nos óleos das turbinas, os efeitos podem ser devastadores para a operação e disponibilidade do equipamento e podem incluir:

- Controles lentos e travamento das válvulas servo, o que pode levar a reparos ou substituições caras

- Tempo de inatividade dispendioso devido a interrupções não programadas

- Atrasos de inicialização de sistemas de controle que não respondem

A demanda por confiabilidade, disponibilidade e operação contínua das turbinas de energia de hoje requer um método eficiente, fácil e confiável para remover o verniz não apenas do óleo, mas também das superfícies metálicas molhadas dentro da máquina

“Você não consegue controlar o que não pode medir”

As soluções de monitoramento da Pall incluem monitores de limpeza de fluidos e indicadores de condições do filtro. Além disso, os sensores de água em linha da Pall fornecem medição em tempo real do conteúdo de água dissolvida em óleos, alertando sobre a formação potencial de água livre prejudicial na caixa de engrenagens e no sistema de óleo lubrificante. A Pall também pode aplicar anos de conhecimento acumulado para ajudar a traduzir dados brutos em informações significativas.

Biblioteca de literatura

Usinas de energia nuclear usam filtros robustos para reduzir custos operacionais e de descarte

O sistema de condicionamento de óleo Pall reduz significativamente os níveis de gás de combustão

Superar a geração de carga eletrostática ao incorporar um novo meio filtrante