What are SUPRApak PLUS Modules?

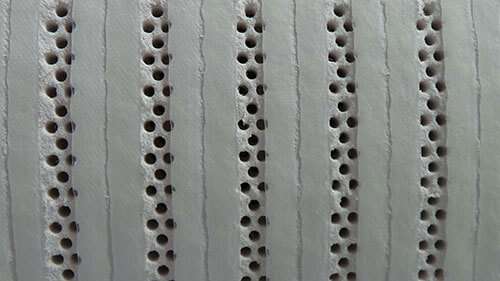

SUPRApak Plus Modules are the second generation of pall's SUPRApak filter series that uses advanced sealing technology to seal the infiltrates to filtrate channels.

Why SUPRApak Plus Modules?

SUPRApak Plus Module is based on a new construction that now allows steam sanitization in the process and offers an optimized dp range for higher total throughput and performance.

| Feature | Benefit | Value |

|---|---|---|

Advanced sealing technology |

|

|

|

| |

|

| |

| Modular design |

|

|

| Ease of handling |

|

|

| Flow configuration based on "edge flow" principle |

|

|

|

| |

| High dirt holding capacity |

|

|

| Compact construction |

|

|

| Filter need no gaskets | No time consuming mainteinance compared to classical sheet filters |

|

| Optimized housing design |

|

|

-

Classical DE Sheet Media

-

Ion Reduced Sheet Media

-

Pure Cellulose Sheet Media

Meet the entire range of removal requirements in the food and beverage industry.. Available in multiple grades suitable for microbial reduction and applications requiring fine, clarifying and coarse filtration.

SUPRApak Plus PW Series Modules

- Meets the entire range of removal requirements in the food and beverage industry. The SUPRApak PW Series are available in multiple grades suitable for applications requiring fine, clarifying and coarse filtration.

SUPRApak Plus PR Series Modules

- Beyond cellulose, kieselguhr and perlite, filter sheet material of the SUPRApak PR-series contain up to 40% of polyolefin fibers, specially selected for best possible filtration results. These filter sheets are characterised by an increased chemical and mechanical stability. They are therefore particularly suitable for the filtration of aggressive media. An outstanding property of the HR-sheets is their high resistance to cellulose-degrading enzymes.

Sheets are acid washed for reduced Calcium and Magnesium contents. For distilled spirits filtration and ion sensitive products to avoid precipitation of Calcium and Magnesium sulfate after filtration.

SUPRApak Plus PH Series Modules (M(12") and S (7.5") - Size)

- Undergo a proprietary treatment that results in extremely low levels of extractable ions making them the ideal solution for distilled spirits applications. A visually bright finished product free from visible particles is one of the main objectives of spirits filtration. Components (C12-16) fatty acid esters, terpenes, proteins or their complex compounds with metals and/or phenols) of some spirits may precipitate if calcium ion levels are too high. Magnesium may also cause precipitations in tannin containing spirits like whisky and brandy. Standard filter sheets contain small quantities of these extractable ions from the raw materials.

Consists of highly fibrillated pure cellulose (produced without the use of any inorganic material such as DE or Perlite.) No ion release, very gentle filtration for Premium Quality Beverages from coarse to microbiological reduction.

SUPRApak Plus PZ Series Modules (M(12") and S (7.5") - Size)

- Consists of pure cellulose filter sheet media and has been developed to meet the needs of the food and beverage industry for very pure depth filters without any DE (Diatomateous Earth) or Perlite.

- Provides excellent filtration performance with full respect to product quality.

- Lowest impact on color and aroma during filtration of high quality products.

For more information on how our depth filtration solutions can support your needs, please contact our team of experts