Preparado para saber mais? Podemos ajudar a encontrar a solução de filtração de vinho certa para suas necessidades. Entre em contato.

Filtração de vinho

A qualidade do vinho é essencial

Filtração de vinho: melhorando a qualidade e a consistência na produção de vinhos

Na produção de vinhos, é essencial preservar a integridade do sabor, aroma e clareza de um vinho. É por isso que escolher o sistema de filtração de vinho certo é fundamental. Desde a remoção de partículas indesejadas até a garantia de estabilidade microbiológica, os filtros de vinho avançados desempenham um papel fundamental na filtração do vinho para a entrega de um produto limpo, estável em prateleira e de alta qualidade.

Por que a filtração de vinho é importante

Contaminantes como cristais de tartarato, resíduos de tratamento, agregados orgânicos, bactérias e leveduras podem comprometer a qualidade do vinho. Filtrar o vinho de forma eficaz elimina esses riscos, mantendo o caráter único e o perfil sensorial do vinho. Quer você esteja esclarecendo o vinho ou preparando-o para o engarrafamento, selecionar os métodos certos de filtração de vinho garante consistência e excelência.

Líderes globais em sistemas de filtração de vinho

Com mais de um século de inovação, a Pall tornou-se um nome confiável em sistemas de filtração de vinho. Nossas tecnologias são usadas por vinícolas de todos os tamanhos, de produtores boutique a marcas globais, em todas as principais regiões produtoras de vinho. Nossas soluções são frequentemente vistas como referências para sistemas de filtração de vinho e sedimentos.

Nosso legado em filtração de vinho:

- Folhas de filtro Seitz®: usadas há mais de 130 anos, essas folhas filtraram mais de um trilhão de litros de vinho em todo o mundo.

- Sistema de filtração de fluxo cruzado Oenoflow. Uma solução revolucionária em filtração de vinho de fluxo cruzado, com mais de 1.500 instalações no mundo inteiro.

Soluções da Pall para o processo de filtração de vinho

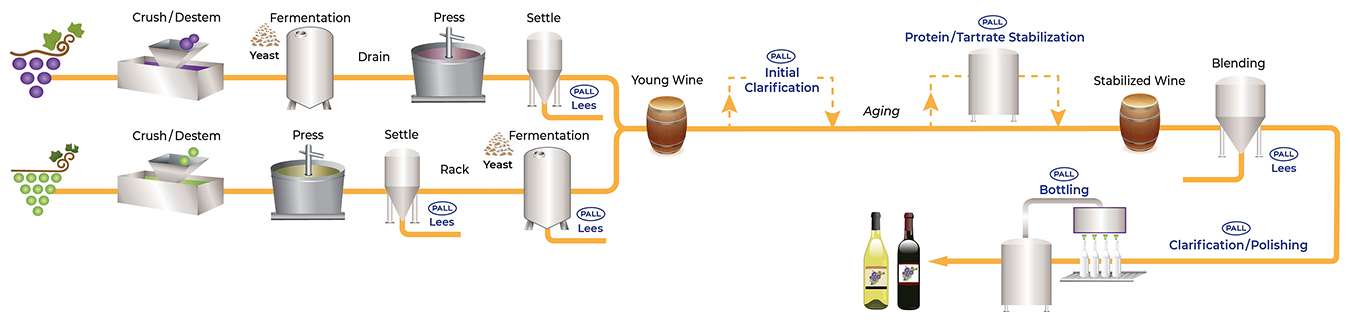

Nossas soluções e nossa experiência no processo de fabricação de vinho são demonstradas abaixo com soluções de sistema de filtração de vinho tradicionais e modernas que preservam a qualidade e mantêm os menores custos operacionais.

-

Clarificação de vinho

-

Filtração de sedimentos

-

Remoção de coloides

-

Estabilização de proteína

-

Engarrafamento de vinho

-

Carvão ativado

Por que a clarificação do vinho é importante?

A clarificação é a etapa principal na filtração do vinho. Leveduras e outras partículas da fermentação e do refino são removidas para reduzir a turbidez e melhorar a capacidade na etapa de filtração.

O sistema Oenoflow PRO XL foi concebido para ajudar as vinícolas a obter clarificação e estabilização de proteína. Outros benefícios incluem:

- Redução no uso de energia para apoiar as metas de zerar as emissões líquidas de carbono

- Redução no uso da água devido à escassez considerável vivenciada em muitas regiões

Recuperação de vinho de valor superior a partir de sedimentos

Borra, o sedimento no fundo dos recipientes de suco, fermentação ou refino, podem representar até 10% do volume total de uma vinícola. A recuperação de vinho e suco a partir das borras representa uma das formas de filtração mais desafiadoras enfrentadas por vinícolas.

A recuperação de vinho e suco a partir de sedimentos é uma das formas de filtração mais desafiadoras com as quais as vinícolas se deparam. O sistema Oenoflow HS é um novo sistema de filtração de fluxo cruzado desenvolvido especificamente para o processamento de sedimentos.

Após a clarificação, estabilização e maturação primárias, agentes de refino, cristais, colóides e bactérias podem ainda estar presentes no vinho. A filtração de polimento é projetada para remover essas partículas e turvação e produzir um vinho mais brilhante, melhorando a capacidade de filtração para a etapa de processamento.

Tecnologias de filtração de profundidade

A filtração de profundidade representa uma ampla gama de mídias de placa filtrante diferentes que podem ser usadas para:

- Remoção da turbidez, desde partículas grossas até finas

- Filtração de polimento

- Remoção de coloides

- Remoção de turbidez a frio

- Remoção de deterioração microbiana/Redução de micro-organismos (levedura/bactérias, mofo).

A estabilização de proteína e a clarificação são duas etapas fundamentais para atender às expectativas do consumidor por um vinho reluzente. Embora ambas as etapas impeçam a formação de turbidez, uma delas para remover proteínas sensíveis ao calor e a outra para remover sólidos suspensos, os processos comerciais convencionais normalmente são realizados em fases consecutivas, adicionando mão de obra, tempo e desperdício ao processo de produção de vinho. Graças ao novo Sistema Oenoflow PRO XL com a funcionalidade Oenofine instalada, as vinícolas podem agora combinar essas operações em uma única etapa e reduzir custos.

Remover contaminantes ao engarrafar o vinho é a chave para garantir qualidade consistente do produto

A filtração por cartucho é vital para remover partículas e microrganismos antes do engarrafamento, evitando a refermentação e sabores estranhos. Um programa de engarrafamento bem estruturado com pré-filtração e filtração final protege a integridade da marca e a qualidade consistente.

Os cartuchos de filtro de bebida Supor®, disponíveis nas classes de 0,45 e 0,65 mícrons, são filtros de membrana hidrofílica que retêm efetivamente os microrganismos de deterioração. Projetados para durabilidade por meio da sanitização repetida com água quente e vapor, eles apresentam um design de pregas otimizado e materiais robustos para maior resiliência e vida útil mais longa.

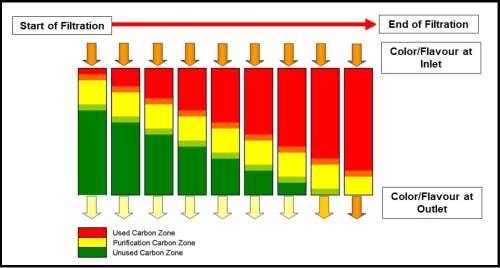

Ajuste de cor e sabor

Combinar aroma inigualável com excelente intensidade de sabor e cor bonita em um vinho é o objetivo de qualquer vinicultor. Entretanto, em alguns casos, o vinho pode ter um sabor ou cor desagradável uma vez que contaminantes podem prejudicar os esforços do vinicultor. A filtração com carvão ativado usando placas impregnadas com carvão ou módulos baseados em placas ou camas de carvão, corrige os problemas de cor e sabor. A Pall oferece tecnologia de filtração por absorção que alcança a correção de cor, sabor e/ou odor. Esses filtros têm uma capacidade de absorção extremamente alta na matriz da placa do filtro. Para lotes pequenos e correções de lote, as placas impregnadas com carvão e os módulos oferecem um modo simples e fácil de tratar o vinho. Saiba mais sobre o Seitz® AKS FB que está em conformidade com o I.O.V (International Organization of Vine and Wine) para o meio de carvão ativado.

Remoção de cloro da água da cidade

O cloro é amplamente usado em suprimentos de água como desinfetante para matar bactérias e patógenos nocivos. No entanto, sua presença na água usada na produção de vinhos pode ter vários efeitos prejudiciais. Resolva esses desafios com carvão ativado.

Filtração de serviços públicos no processo de produção de vinhos

Garanta a qualidade dos fluidos de serviços públicos — como água, vapor, ar e gases — para proteger o processo de produção de vinho. Nossos filtros e sistemas de vinho ajudam a remover cloro e outros contaminantes que podem afetar a qualidade do vinho.

Produtos em destaque

Recursos

Perguntas frequentes

O que é filtração de vinho e por que ela é importante?

A filtração de vinho é o processo de remoção de partículas indesejadas, micro-organismos e turbidez do vinho para melhorar a clareza, estabilidade e prazo de validade. Ela desempenha um papel fundamental na manutenção da qualidade do vinho e na prevenção da deterioração após o engarrafamento.

Quais são os métodos de filtração de vinho mais eficazes?

A Pall oferece vários métodos de filtração de vinho, inclusive clarificação, pré-filtração e filtração por membrana final. A filtração final é especialmente importante para remover organismos deteriorantes como Oenococcus oeni e Dekkera bruxellensis, que podem causar sabores ou refermentação.